#Industry News

What Is Surface Roughness?

A Comprehensive Guide

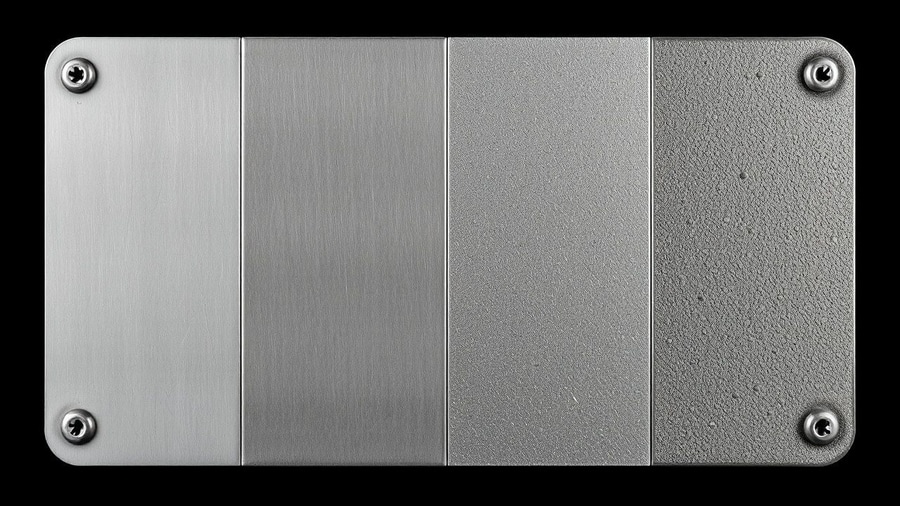

Surface roughness is the small-scale, irregular deviations from the ideal smooth surface of a material. It's a measure of the surface's texture, characterized by the height and spacing of these irregularities. Key parameters include Ra (arithmetical mean roughness), Rq (root mean square roughness), Rz (average peak-to-valley height), and Rmax (maximum peak-to-valley height). These parameters help quantify and compare surface roughness in manufacturing and quality control.

Surface roughness is influenced by factors such as the manufacturing process, material properties, and environmental conditions. For example, machining processes like milling, turning, and grinding can produce different roughness levels based on the tool, speed, and feed rate. Material hardness and ductility also affect roughness when processed similarly.

Understanding and controlling surface roughness is crucial in industries like automotive, aerospace, and electronics. In automotive, it affects engine component friction and wear, impacting fuel efficiency and engine life. In aerospace, it influences the aerodynamic performance of aircraft components, affecting fuel consumption and flight stability. Surface roughness is a critical parameter that impacts the performance, durability, and functionality of materials.