#Industry News

Deep Draw Stamping

Definition & Advantage

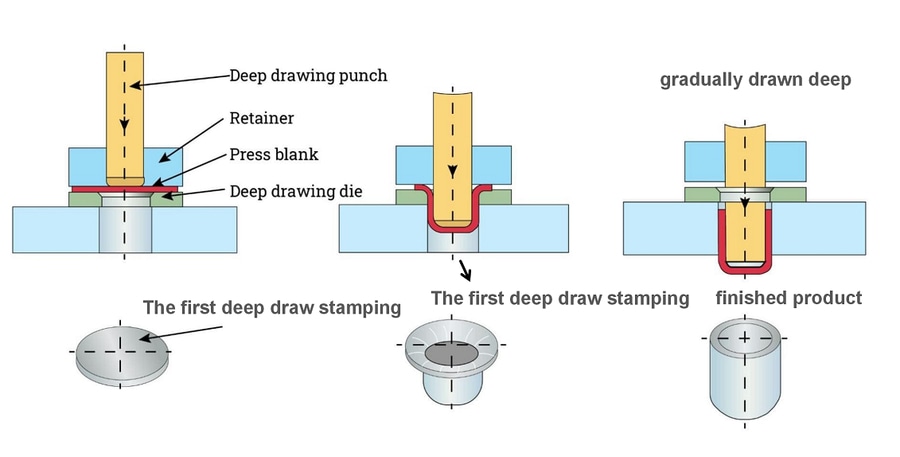

Deep drawing stamping is a metal forming process in which a metal sheet is placed into a mold and gradually formed into the desired shape through stretching and pressure. It is often used to create deep and thin metal parts.

Deep drawing stamping forms sheet metal into closed-bottom, round or irregularly shaped cup or cylindrical products while stretching and compressing it.

There are two methods of deep drawing: drawing and stamping through a stamping machine and drawing and stamping using a hydraulic press.

It is often used in the production of some parts, such as automobile body parts, kitchenware, containers, etc.

Deep drawing usually involves multiple operations in the same process, such as gradually drawing the metal sheet into the desired shape along the depth of the mold. This is a common and effective metal forming method that is widely used in manufacturing.

This process requires that the metal sheet be malleable enough to smoothly conform to the shape of the mold without cracking or damage.

Deep drawing stamping can effectively manufacture parts with complex and deep geometries. Because deep drawing stamping usually uses automated equipment and multi-process molds, it performs well in high-volume production. Multiple similar parts can be quickly manufactured in one deep drawing process, thereby improving production efficiency and high material utilization.