#Industry News

Common Casting Materials

5 types of common raw materials for casting products

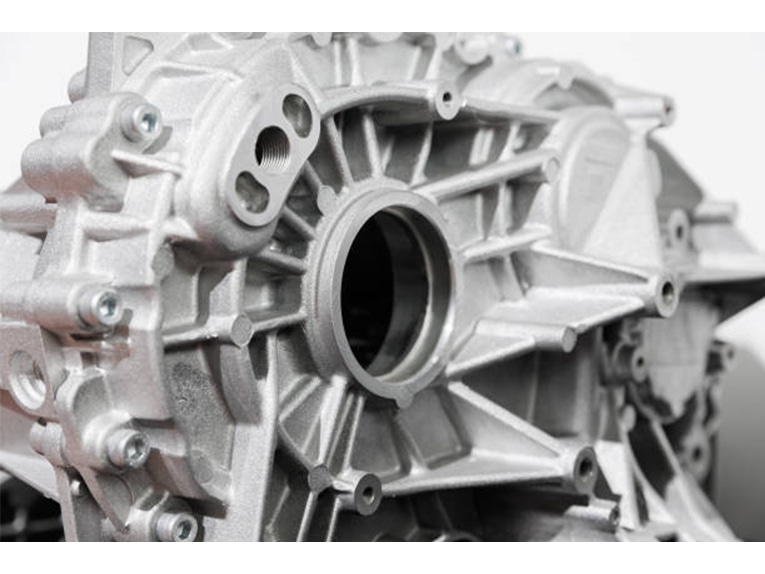

Casting is a key process in manufacturing that involves pouring molten metal or other materials into molds to create parts and products of various shapes. Choosing the right casting material is critical to ensuring product quality and performance. Common casting materials include aluminum alloy, zinc alloy, cast iron, magnesium alloy and copper alloy.

Aluminum alloy is widely used for casting due to its lightweight, high strength, and excellent thermal conductivity. It can be shaped into various forms through conventional casting, die casting, or sand casting processes. Because of its workability, aluminum alloys find applications in automotive, aerospace, and electronic industries.

Zinc alloy is an economical casting material known for its corrosion resistance and malleability. It is often used in manufacturing automotive parts, household items, and decorations.

Cast iron, containing a significant amount of carbon, is valued for its affordability, durability, and ability to withstand high pressure and wear. It is commonly utilized in machine parts, pipes, and automotive components.

Magnesium alloy is a lightweight material prized for its strength and weight-saving properties. It is frequently used in the production of automotive parts, aerospace components, and handheld devices.

Copper alloy, known for its good electrical and thermal conductivity, as well as its processability, is widely used in electrical appliances, electronic devices, and piping systems.

If you want to know more detailed information about casting materials, such as the characteristics of various materials, suitable application fields. please click the link on the lower right to view the original text.