#Industry News

How Do Self-Tapping Screws Work?

How Do Self-Tapping Screws Work?

Self-tapping screws are a type of screw that can create their own threads as they are driven into a material, eliminating the need for pre-drilled holes. Here's a detailed explanation of how they work:

General Principle

The core principle behind self-tapping screws is their ability to cut or form threads as they are inserted into the material. This is achieved through a combination of their sharp, tapered point and thread design. As the screw is turned, it either cuts away material to create a thread or displaces material to form a thread around the screw. This process is similar to using a tap to create threads in a hole, but it's done by the screw itself as it is driven in.

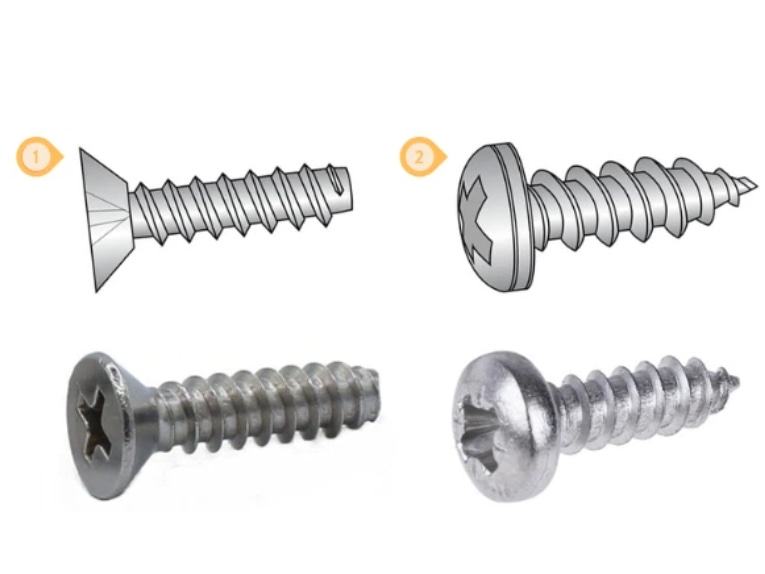

Different Types and Their Working Mechanisms

Self-tapping screws can be broadly categorized into three types based on how they create threads:

1. Thread-Cutting Screws

Mechanism: These screws have sharp cutting edges on their threads, often resembling the flutes of a drill bit. As the screw is driven into the material, these cutting edges remove material to create a thread. This process is similar to cutting a thread into the material with a tap.

Application: Thread-cutting screws are suitable for harder materials such as metals and thick plastics. They are particularly effective when the material is too hard to be easily displaced or when a clean thread is required.

Example: Type F self-tapping screws have thin vertical cutting slits that help in cutting through the material to form threads.

2. Thread-Forming Screws

Mechanism: Unlike thread-cutting screws, thread-forming screws do not remove material. Instead, they displace the material around the screw to form a thread. The threads on these screws are designed to push the material out of the way as the screw is driven in, creating a thread that tightly fits the screw.

Application: Thread-forming screws are ideal for softer materials such as wood, thin metal sheets, and plastics. They are commonly used when a clean, undamaged thread is required and when the material is too thin or brittle to be pre-tapped.

Example: Type B self-tapping screws have blunt tips with threads that are closer together, making them suitable for softer materials.

3. Thread-Rolling Screws

Mechanism: Thread-rolling screws have specially designed helical ridges. As the screw is driven into the material, these ridges compress the material into a thread. This process results in a very tight fit with zero clearance, as the material is rolled into shape rather than being cut or displaced.

Application: Thread-rolling screws are used in applications where a very strong and precise thread is required. They are particularly effective in materials that can be easily compressed without breaking.

Example: Thread-rolling screws are often used in precision engineering and electronics, where a secure and accurate connection is crucial.