#Industry News

The Micropack packaging machine that thinks differently

A new software for the versatile hand-loaded Imanpack

Our customers have always chosen Micropack Pro Bagmatic when they need to pack delicate products (such as chrome products), irregularly shaped products (such as collapsible ducts or faucets), or products of varying sizes and small batches by allowing quick transition between products with manual loading. This is achieved by a special loading belt equipped with 'fingers' that help the operator position products at the correct distance.

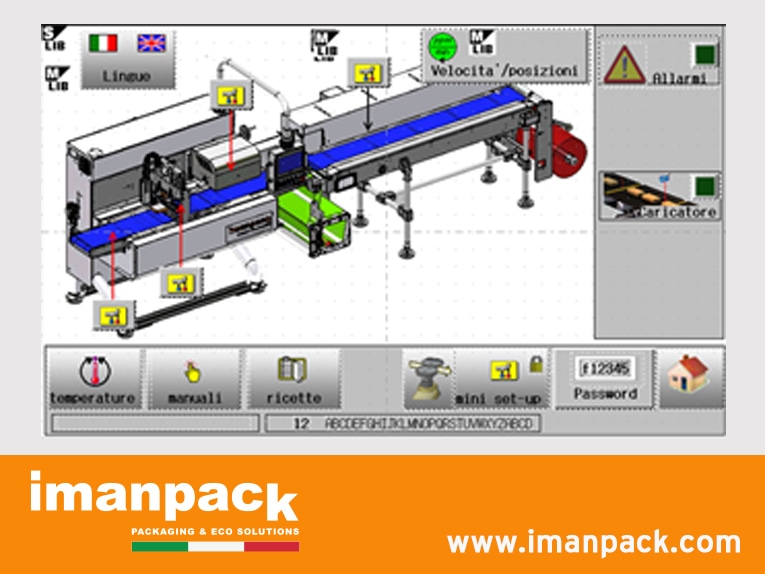

In addition to this, our programmers have developed new software for Micropack Pro Bagmatic, whose interface promises unprecedented ease of use. The convenient operator panel allows you to select different operating modes, change machine speed or package cutting and film tension (or slack), in an agile and intuitive manner.

Intuitive settings from the HMI panel

With a simple touch on the 3D representation of the machine in the HMI (e.g.: on the cutter or on the loading conveyor), you can change parameters such as the opening and closing steps of the transverse sealing system or the number of 'fingers' spacing the products on the conveyor. In addition, thanks to the rapid axis motion check function, the operation of each component can be examined by simply selecting it from the 3D representation.

Always tailored packages

A new set of electronic controls and software allow the Micropack Pro Bagmatic to automatically adjust the length of the package, compensating for any variations in the 'extensibility of the film used. In addition, thanks to a highly precise temperature control system for the sealing parts, the Bagmatic ensures stable sealing without running or burning the film.

After a break, restart immediately

The new software allows work to resume automatically after any breaks, without the need to reset data. This advantage translates into significant time savings, as the machine performs the 'homing' procedure only when the electrical cabinet is turned on. Dopo una pausa, riparti immediatamente

Quick format changeover, big film savings

The quick format changeover function allows very fast switching between products, without wasting film. An example? From the control panel, the operator can set to pack a product twice as long as the previous one. The machine then empties itself of the previous product, phases in the new, longer product, and can restart immediately, avoiding unnecessary film waste as well as a complete machine reset.

Safer and safer

To further increase operator safety, we have implemented additional controls that not only stop the machine in an emergency but also verify that the safety circuit is working properly in a preset time.

At Imanpack Packaging & Eco Solutions, we have always been attentive to the changing needs of the market and are committed to offering solutions that combine production flexibility, operator safety and waste reduction, while fully respecting the environment. If you would like more information or to request a customized offer, please contact us directly at info@imanpack.it.

We will be happy to explain the quality of our products and provide you with our best service.