#Product Trends

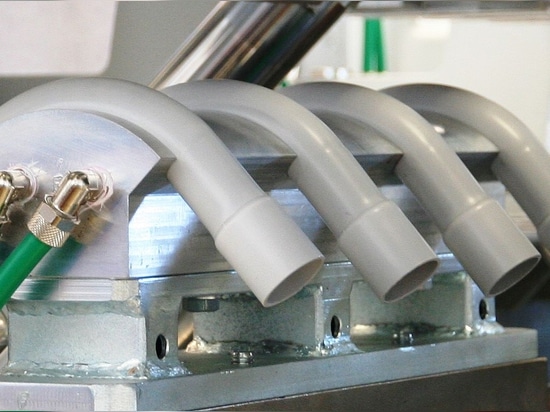

NEW Injection Socketing Machine BA/INJ, for double-walled corrugated plastic pipes

Ipm s.r.l. is happy to introduce the New injection socketing machine, for double-walled corrugated pipes.

Ipm s.r.l is an international company, with 28 years of experience, leader in the production of down-stream equipment of plastic pipe extrusion line.

New injection socketing machine, for double-walled corrugated pipes, fully automatic, it is a machine able to inject the socket on the pipe, in the pipe-line, from outside-diameter 110 mm up to outside-diameter 1200 mm.

This machine guarantee different benefits also compared other systems already present on the market: Standard handling of pipes with different lengths during the production (max. length 12.000 mm), high performance, fast processing preventing any decrease of the extrusion speed, perfect welding of the injected material with the pipe, reliable strength of the socket texture, certified permanent geometrical and dimensional stability of the socket, even when subjected to the harshest environmental temperatures, extreme flexibility of the process, which allows to exploit both virgin material (PP and PE) and regenerated material, possibility to manufacture double sockets (joints) by off-line operation, user friendly machines managed by just one operator, easy and quick tool changing, remarkable energy and economy saving, saving in gaskets (since just one is needed for the joint).

Broad range of models suitable on the market are: BA 500/INJ (for pipes O.D 110 - 500 mm), BA 680/INJ (for pipes O.D 160 - 630 mm), BA 900/INJ (for pipes O.D 160 - 800 mm), and BA 1200/INJ (for pipes O.D 200 - 1.200 mm).

In very short time, thanks to all the advantages of such machines, we have been able to sold and deliver all these machine models, over listed, around the world.

In case you are interested to receive more information (technical information or quotations) about this machine, please don’t hesitate to contact us. We will be happy to satisfy all your request in the shortest time possible