#Industry News

Model R: Momentum in Refurbished Machinery

In the last few years, there has been a growing interest in refurbished machinery. This is because it offers a sustainable solution at a cost-effective price.

Recent Success Stories

Model R is revolutionizing the way that company’s source and purchase refurbished equipment. “We’ve been able to help so many companies reduce their environmental impact while saving money at the same time,” says Rex Pattyn, Customer Care Sales Manager for JBT Diversified Food & Health. “The overwhelming response from customers has been very positive, which is great! I think there are a lot of companies who can benefit from an industry-standard JBT machine complete with warranty at a very attractive price.”

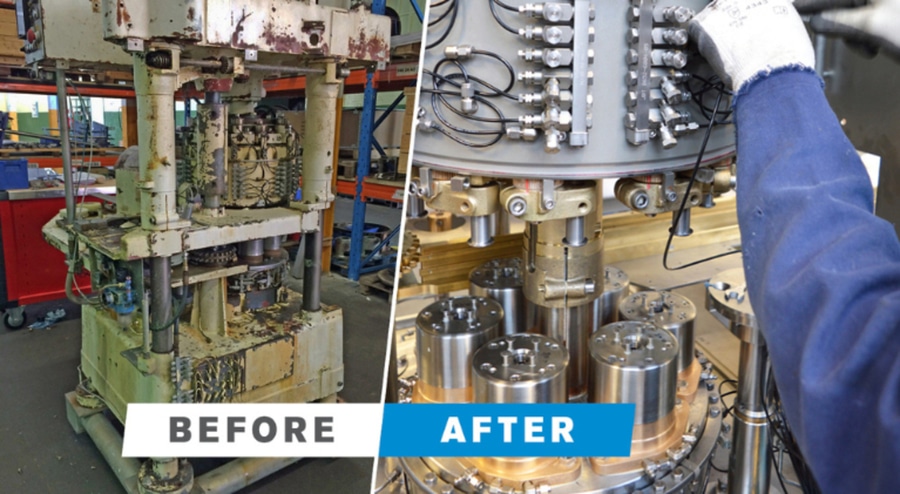

Model R equipment being adjusted by JBT technician

Short Lead Times

The rapid delivery of refurbished equipment is a significant advantage over new equipment. In some cases, lead times are so short that you can get your hands on equipment within four months, depending on availability.

JBT can achieve this short lead time due to the ability to use the existing parts. These are machines that we buy back from customers and – after the thorough overhaul – we can offer them to other customers, resulting in customers getting a nearly new machine. This avoids the need to process raw materials and machine them into a final product.

After all, if you need equipment up and running as soon as possible with a full warranty and cannot wait for it to be built from scratch, buying refurbished is the only way to go

Outstanding Quality

If you are looking for a cost-effective solution that uses high quality refurbished machinery, then look no further than our Model R line. We test and repair all our products before selling them. We consider a rebuild as an order for a complete, new JBT machine. Consequently, the rebuilt operation is supervised by a dedicated Project Manager.

“All wear & tear parts are discarded, and we execute a risk assessment on all recycled parts” says Johan Van Riet, Customer Care Business Development Manager. “We re-install the thoroughly checked parts, making sure they are updated and compliant to the latest standards” This attention to detail allows for performance just like a new machine.

This attention to detail ensures that refurbished equipment performs just like a new machine, and customers also receive a full warranty with their Model R purchase, including Factory and Site Acceptance Tests. In addition, JBT provides installation, commissioning, and on-site training for operators.

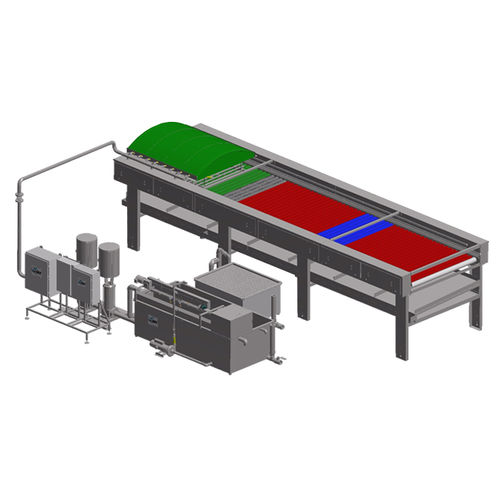

Model R machine being upgraded

Reducing Impact with A Circular Economy

By choosing a Model R solution you recondition your future uptime ensuring product quality, food safety, longer shelf-life, reduce emission, and lower Total Cost of Ownership. The United Nations’ International Resource Panel concluded that natural resource extraction and processing contribute to about half of all global greenhouse gas emissions. By reusing, repairing, refurbishing, and recycling existing materials and equipment as long as possible, JBT creates a circular economy with its customers, helping to reduce waste of old equipment and reduce the emissions involved in manufacturing new equipment.