#Product Trends

The steel materials used by JINPAT slip rings

As a highly customizable industrial product, slip rings use a variety of different materials, such as various plastics, adhesives, copper alloys and aluminum alloys with different ratios, and various grades of steel.

After processing, these materials are used to manufacture various parts of the slip ring, making it an industrial component that can transmit electrical energy, gases, liquids, and various optoelectronic signals while rotating 360 degrees.

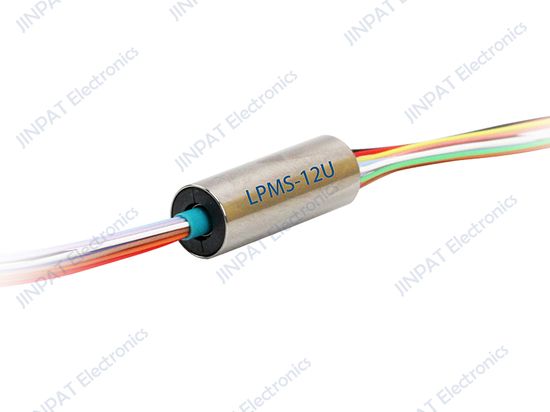

In the slip rings developed by JINPAT, the use of steel is very common. Customized capsule and hollow shaft slip rings usually use steel as the shell and main shaft material. Some fiber optic slip rings usually use steel as the shell. The full range of high current slip ring products usually use steel as the shell material. Like other materials, steel is divided into ordinary carbon structural steel Q235, 304 stainless steel, 316 stainless steel, 42CrMo ultra-high strength alloy steel according to different material ratios.

Taking the JINPAT LPA series high current slip ring as an example, Q235 steel is the most frequently used material, which is commonly used in products that do not require ultra-high protection levels or high anti-vibration levels. Using Q235 steel can reduce the cost of high current slip rings and make the product very cost-effective. Of course, steel can also be used in explosion-proof slip rings and products with special protection and anti-vibration requirements. Just increase the thickness of the steel and adjust the internal and external structural design of the product according to the operating environment of the slip ring application terminal device.

In the slip ring industry, the frequency of using 304 stainless steel is slightly lower than that of Q235 steel. It is commonly used in fiber optic slip rings, custom capsule and hollow shaft slip rings, and high current slip rings. 316 stainless steel and 42CrMo ultra-high strength alloy steel are usually used as shell materials for some special industrial field high current slip rings. Compared with high current slip rings using Q235 steel, the Crystal-Phase LPA high current slip rings that use these stainless steel materials as the shell generally have an IP64+ protection rating. Some models of slip rings also have higher explosion-proof ratings and can be used on oil drilling platforms.

For example, LPA000-0440-0663-0310-10S is a high current product suitable for cranes on oil drilling platforms, with a large amount of 316 stainless steel material used for its shell. On the other hand, LPA000-0350 is also a high current slip ring suitable for the drilling system on oil drilling platforms, with an ultra-high explosion-proof rating. In addition to using 316L steel as the shell material, it also uses 42CrMo ultra-high strength alloy steel as the main shaft, and has waterproof function under 60MPa through advanced structural design and the application of stainless steel materials.