#Industry News

Selection of slip ring foundation materials

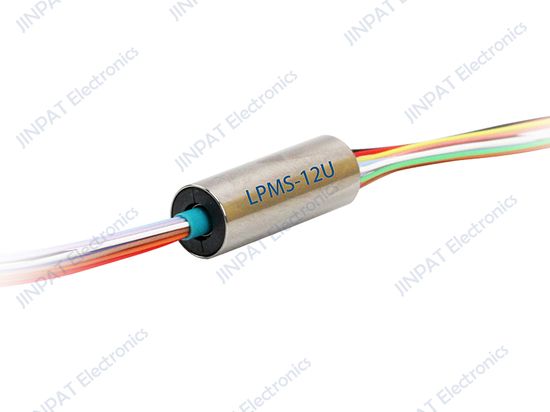

For slip rings, excellent performance is closely related to the selection of foundation materials, such as small pancake slip rings.

In order to maximize cost savings while ensuring product performance, most slip ring manufacturers typically choose PCB boards that have already been mass produced as the housing material, which is also the method used by JINPAT.

Large slip rings typically require the transmission of large currents, and pancake slip rings are no exception. For large pancake slip rings with many channels, large diameter, and high material consumption, PCB materials are no longer suitable. This material is relatively expensive compared to other injectable materials, and also has some performance drawbacks.

For such pancake slip rings, commonly used housing materials include electric wood (phenolic plastic) or fiberglass. These two materials provide high mechanical strength and excellent insulation and heat resistance properties to the slip rings, while also enabling better control of production costs. In the slip ring industry, electric wood is far more widely used than fiberglass because it can be processed through injection molding, which is more favorable for slip ring applications.

As electric wood is an injectable material, it is not only used in large pancake slip rings but also commonly employed in other types of slip rings, such as those used in medium to large-sized generators. In such cases, the rotor copper rings, output copper blocks, and electric wood are cast together as a unified structure. However, these types of slip rings usually have fewer circuits. In some small-sized, multi-channel slip rings that require the transmission of high currents, electric wood material and similar casting techniques are also used. These types of slip rings typically employ carbon brush friction pairs. However, JINPAT has not adopted this approach in such slip rings but instead opted for other materials and employed a modular design to flexibly address the number of circuits.

In addition to electric wood, slip rings also commonly use materials such as polypropylene and engineering plastics. There is a wide variety of these injection-moldable materials based on different composition ratios. Over the past 20 years of entering the slip ring industry, JINPAT has conducted year after year of experiments, verifying hundreds of different composition options for slip ring injection materials. This accumulation of valuable experience has laid a solid foundation for the selection of key materials in slip rings. It is this foundation that enables JINPAT slip rings to possess outstanding product quality and superior performance.