#Trade Shows & Events

Gyroscope and Multi-Axis Simulation Turntable Slip Ring Technology

Gyroscope and Multi-Axis Simulation Turntable Slip Ring Technology

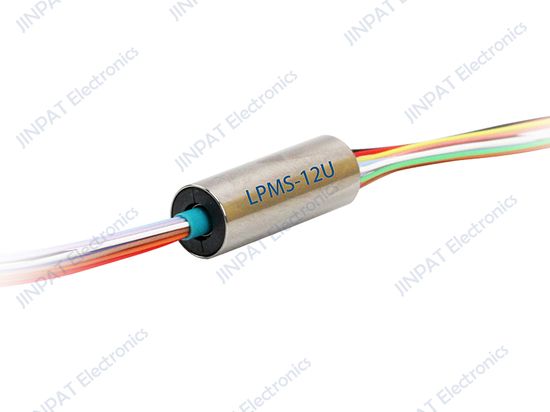

Gyroscopes and multi-axis turntables are electromechanical devices with the same structure. Normally, gyroscopes are integrated with accelerometers and used in platform-based inertial navigation systems. In order to transmit the data signals generated by the gyroscope, slip rings are installed on their rotation axes. As a compact electromechanical system, the slip rings used in gyroscopes are also very small in size. JINPAT specializes in developing miniature slip rings for gyroscopes, primarily in the LPMS series custom products. These slip rings typically have more than 40 channels, and all of them support the mixed transmission of signals and power.

One of the most typical slip rings developed by JINPAT for gyroscope systems is the LPMS-44S. Several years ago, this product was expensive and had poor after-sales support. In response to this situation, JINPAT, as one of the leading slip ring manufacturers, made multiple improvements and iterations. As a result, the diameter of the LPMS-44S slip ring was reduced from 16mm to 15.5mm, and also developed a flanged model based on this.

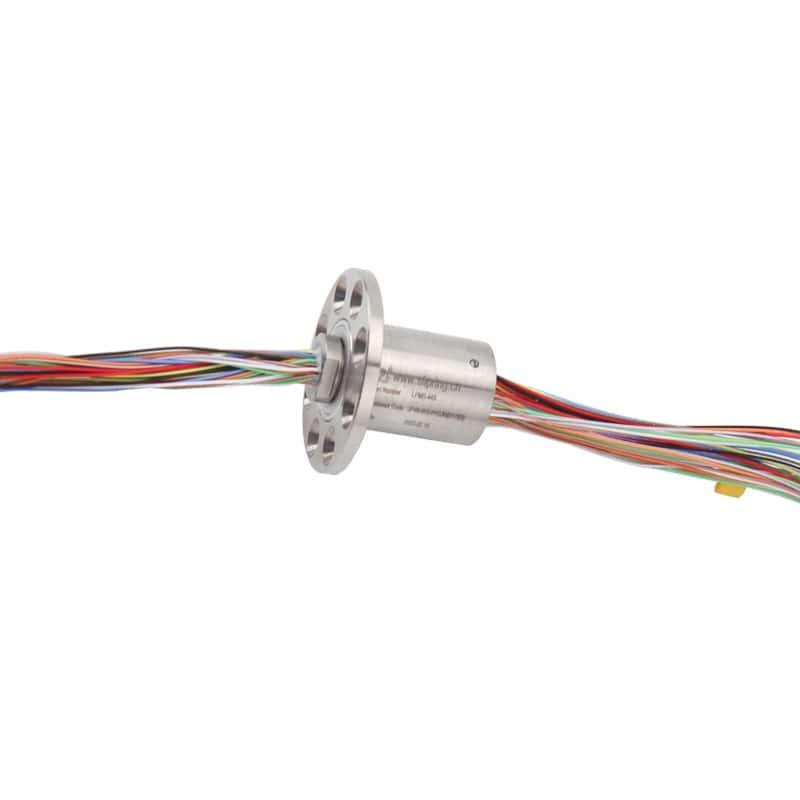

JINPAT has also developed ultra-miniature slip rings for gyroscopes, including models with 60, 80, and 90 channels. The diameters of these products are also around 15mm, making them very compact. Compared to the slip rings used in dry gyroscopes, those used in multi-axis turntables are slightly more complex. These products not only integrate power rings but also incorporate Ethernet signal channels. The slip rings installed on multi-axis turntables include capsule slip rings and through-hole slip rings. Typically, the same model of slip rings is distributed on the three axes of the test bench, achieving high-speed data transmission through USB or Ethernet signals. They support the use of Gigabit Ethernet and USB 2.0 signals in series.

JINPAT slip rings developed for multi-axis turntables also have some unique technical advantages. For example, the hollow shaft products adopt an advanced cluster-brush multi-point contact method, and the ultra-high surface finish of the copper rings ensures smooth operation of the friction pair, thus ensuring reliable contact. The precious metal contact friction pair enables the slip rings to have an extremely low bit error rate (BER) when integrating Ethernet signal channels. The products can also be designed with special structures to solve the problems of crosstalk and excessively low return loss.