#Product Trends

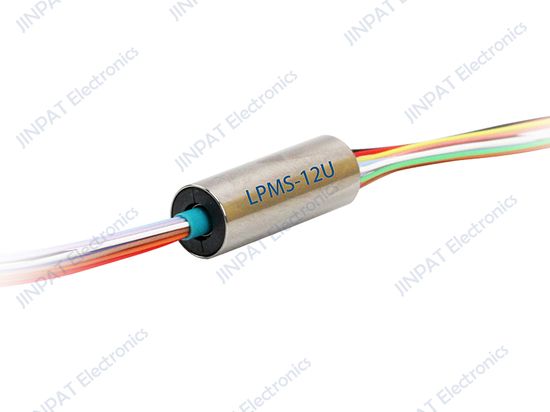

Single-mode multi-channel fiber optic slip rings require high demands on machining processes.

As a specialized type of slip ring, fiber optic slip rings stand out because their transmission medium is laser.

In the development process, traditional conductive slip rings need to meet various electrical performance requirements, while the main challenge of fiber optic slip rings lies in matching their optical performance. Fiber optics can be divided into single-mode and multi-mode types, and these two specifications of fibers have slightly different optical transmission capabilities. Fiber optic slip rings can also be classified into single-mode and multi-mode based on the type of fiber used. Due to the larger core diameter of multi-mode products, their development difficulty is relatively lower.

Like many slip rings, fiber optic slip rings can be either multi-channel or single-channel. Compared to single-channel products, multi-channel fiber optic slip rings pose greater challenges in their development, especially multi-channel single-mode fiber optic slip rings. The more channels there are, the greater the manufacturing difficulty, and each additional channel can even lead to an exponential increase in manufacturing complexity. This is because the core diameter of single-mode fiber optic slip rings is extremely small, making them highly sensitive to variations in parameters such as insertion loss in the transmission of fiber optic slip rings.

Currently, manufacturers including JINPAT have their own standards for machining fiber optic slip ring components. For example, JINPAT specifies that, under certain diameters, the machining tolerance of the components should be controlled within the h8 range. This precision standard can meet the requirements of most multi-channel multi-mode fiber optic slip rings, but it is still far from sufficient for multi-channel single-mode fiber optic slip rings. Under this design precision premise, even if the manufactured multi-channel fiber optic slip rings pass the initial inspection, the wear of components caused by machining precision can still potentially affect the transmission of fiber optic signals after a period of operation.

To enhance the optical performance of multi-channel single-mode fiber optic slip rings and control their insertion loss within an acceptable range, engineers have explored various methods. In addition to using higher precision optical components and superior optical structures within the fiber optic slip rings, improving the manufacturing precision of the metal components of the slip ring rotor and stator is also crucial. After all, the wavelength inside fiber optic slip rings is counted in nanometers, while the metal components of the slip ring rotor and stator are currently measured in millimeters. It would be ideal to control their tolerance range below 0.01 millimeters, although this may result in higher costs.