#Product Trends

Differences and Similarities of Marine Crane and Marine Winch Slip Rings

Differences and Similarities of Marine Crane and Marine Winch Slip Rings

Cranes and winches are the most common equipment found on special-purpose vessels, whether they are ordinary civil engineering vessels, research vessels, or warships. Slip rings are essential components on cranes, mounted on the axis of the equipment's rotation center. They are responsible for transmitting power signals between two rotating ends and addressing the issue of wire entanglement during infinite rotation.

Due to platform tonnage considerations, marine cranes on special-purpose vessels have lifting capacities one level higher than those of land-based engineering machinery. Higher lifting weights imply the need for greater power output. Consequently, marine crane slip rings typically adopt carbon brush-type high-current slip rings as the primary solution. In addition to the high-current module, JINPAT has developed slip rings for marine cranes that can also integrate low-current and signal modules. To meet the operational requirements in tropical and polar regions, these slip rings can be equipped with internal cooling fans or heaters.

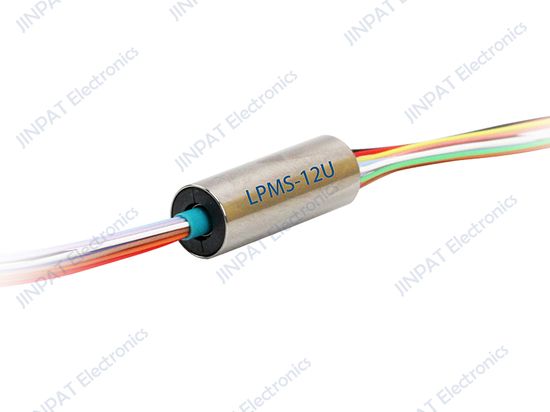

Due to different assembly scenarios, crane slip rings are vertically mounted, while winch slip rings are horizontally installed. Winch slip rings are also common equipment on various types of vessels, but compared to marine crane slip rings, they are used mainly for transmitting ordinary weak electrical signals. The signal transmission in marine winch slip rings is more complex, and some high-end products for underwater winches even require multi-channel single-mode fiber optic slip rings to address the signal transmission issue.

As a result of the different purposes of cranes and winches, the external shapes of the two types of slip rings differ. Marine crane slip rings are typically housed in slip ring boxes, while marine winch slip rings are cylindrical or large through-hole types. Through-hole slip rings are primarily traditional conductive slip rings with very few integrated electrical and signal modules, while cylindrical structures offer more operational space and the ability to integrate multi-channel fiber optic slip rings, weak electrical signal modules, and other components.

Based on examples provided by JINPAT, the maximum operating voltage of winch slip rings is usually higher. Marine crane slip rings rarely exceed 690V, while marine winch slip rings often have products capable of operating at voltages exceeding 2500V. This is determined by their respective working scenarios. To stably transmit electrical energy over longer distances, marine winch slip rings require higher voltages, whereas marine crane slip rings do not have this requirement and can directly use standard ship voltages.

Furthermore, both types of JINPAT slip rings share some common features. They both possess strong anti-vibration capabilities, meeting various ship anti-vibration standards specified in GB and GJB. Additionally, both slip rings have high levels of protection, with the highest rating reaching IP66. Due to the internal structure of high-current slip rings, both types are typically designed with maintainability in mind and have good serviceability.By gaining in-depth knowledge of the differences and similarities between JINPAT marine crane and marine winch slip rings, ship designers and manufacturers of marine equipment can make better choices when selecting suitable slip rings for their applications, ensuring the efficient operation and reliability of shipboard equipment.