#Product Trends

Slip Rings for Smart Agricultural Electromechanical Equipment

Slip Rings for Smart Agricultural Electromechanical Equipment

The development of agricultural mechanization is driving agriculture towards further intelligence. As a future trend in this field, an increasing number of smart agricultural electromechanical devices are being employed, and the slip ring industry is poised to benefit from the intelligence of agricultural equipment. Currently, the intelligence of agricultural electromechanical equipment is progressing in two directions. One is the intelligence upgrade of traditional large-scale agricultural machinery, which greatly liberates labor by allowing a single operator in a control room to manage multiple devices. The other direction involves the emergence of robots used for various purposes in intensive planting management scenarios such as large-scale plant factories.

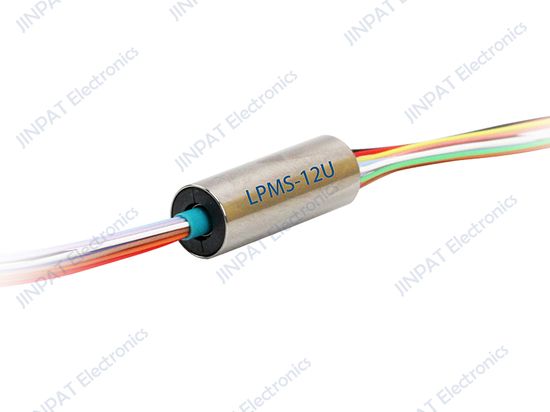

As a renowned manufacturer in the international slip ring industry, JINPAT has provided numerous excellent slip ring solutions for both traditional and intelligent agricultural electromechanical equipment. Currently, the most significant demand for slip rings in intelligent agricultural electromechanical equipment comes from agricultural robots. Unlike industrial robots, agricultural robots are not fixed in one location; instead, they are typically mounted on small chassis that can maneuver along planned paths and make autonomous decisions about their routes. These agricultural robots represent a fusion of lightweight chassis technology and small industrial robot technology. Therefore, like some other robots, they are equipped with a dedicated slip ring for signal and power transmission.

Compared to industrial robots, the most commonly integrated feature in smart agricultural robots is machine vision. Through training, machine vision enables agricultural robots to automatically identify various mature vegetables and fruits, among other capabilities. In the field of industrial robots, there are also specialized machine vision robots. Typically, these robots use slip rings with integrated high-definition video signal pathways to address the challenges of visual transmission. JINPAT offers high-definition video signal slip rings in two categories: one integrates HDMI and DP signals, and the other integrates SDI signals. The most common solution for machine vision is the SDI signal due to its significantly higher cost-effectiveness compared to DP and HDMI signals.

In slip rings for smart agricultural robots, besides solutions using SDI signals for machine vision, some agricultural robots opt for USB signals for visual signal transmission. The through-hole slip ring LPT045-U2-06S, developed by JINPAT for harvesting robots, is a typical product that uses USB cables for transmitting machine vision signals. The choice of this technological approach is based on two factors: first, the visual image signal resolution for harvesting robots does not require ultra-high definition, and second, the USB signal line in the slip ring can also be used as the power line for the robot's camera. Ultimately, the decision is driven by cost-effectiveness and adaptability.