#Industry News

Characteristics of internal and external structures of different types of slip rings

Characteristics of internal and external structures of different types of slip rings

Regardless of the type of industrial product, structure is an important factor determining its performance, and for slip rings, the importance of structure cannot be denied. Different types of slip rings have different application scenarios. For example, the pancake slip ring designed with a flat structure is particularly suitable for installation in equipment with very small axial space. The slip ring designed with a separated structure can be applied to some platforms that require quick disassembly or timely maintenance because of its convenient installation. The through-hole type slip ring can be quickly installed on the transmission shaft and other rotating parts.

In addition to the installation adaptability brought by the external structure, the internal structure of the slip ring is also very important, which determines the service life of the slip ring and is one of the important factors in electrical performance. As an established manufacturer in the field of slip ring manufacturing for nearly 30 years, JINPAT has a sound verification process for slip ring structures. Since the establishment of the R&D center, JINPAT Laboratory has verified over a thousand different slip ring structures and applied these verified slip ring structures to standard and customized products.

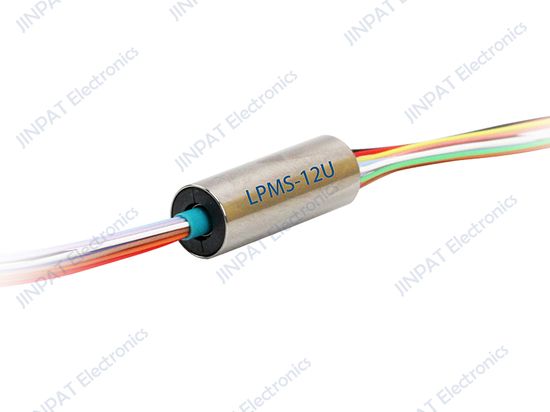

Taking a small capsule slip ring as an example, JINPAT has developed products on this series of slip rings, such as long-life slip rings, high-speed slip rings, and IP68 high protection level slip rings. The common feature between long-life slip rings and high-speed slip rings is that their lifespan exceeds one billion revolutions per minute. The difference is that low-speed slip rings with a hundred revolutions per minute can work for many years, while the lifespan of high-speed products with a speed of over 20000 revolutions per minute is determined by the startup time. The internal structure differences between these two products are very significant, and different structural designs give them unique electrical and mechanical characteristics.

In addition to electric slip rings, there are also some special types of slip rings with unique structural designs, such as fiber optic slip rings and high-frequency slip rings. Due to the transmission of optical signals, the fiber optic slip ring uses optocoupler components inside and does not require friction pairs. Therefore, its structure and electric slip ring have a large diameter, and the frictionless structure of the fiber optic slip ring also gives it a very long lifespan. After replacing the high-speed bearing, its designed working speed can reach tens of thousands of revolutions. Although high-frequency slip rings mainly transmit RF and high-definition video signals, they still belong to the category of electric slip rings. However, their internal structure is also different from ordinary electric slip rings. For example, the high-frequency sliding ring LPHF-05D produced by JINPAT for antenna bases adopts a multi contact structure, which can effectively reduce phase jitter and is suitable for high-capacity data transmission without delay.