#Product Trends

INPAT’s Innovative Cable Winch Slip Ring for Enhanced Efficiency and Reliability

INPAT’s Innovative Cable Winch Slip Ring for Enhanced Efficiency and Reliability

Currently, umbilical cables in water jet burying machines are typically stored using coils. However, this method is impractical for smaller ships, as it requires large storage spaces and additional manpower for handling and storage. To address this issue, cable winch equipment has been introduced.

As a crucial component of cable winches, the conductive slip ring plays a vital role in ensuring continuous power and signal transmission between surface equipment and underwater devices. It connects the mother ship with the underwater burying machine, maintaining uninterrupted communication and functionality.

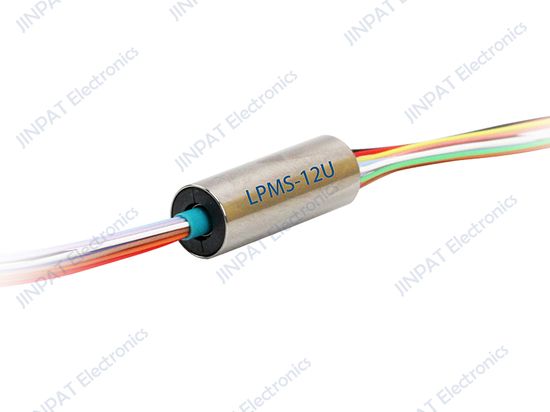

Recently, JINPAT has introduced a new cable winch slip ring that stands out in the field of marine slip rings. This innovative product offers exceptional transmission capabilities, supports high working voltage and current capacities, and boasts strong insulation properties. Moreover, it is designed to function reliably in harsh environments, making it highly adaptable to demanding marine conditions.

The JINPAT slip ring is engineered with a 9-loop integrated design, featuring a stainless steel shell treated with anti-corrosion measures to effectively combat salt spray erosion. It can withstand extreme temperatures, operating smoothly in environments ranging from -20°C to 60°C. With a working voltage of up to 6000VAC and a current capacity of 120A, this slip ring can easily handle high load conditions, ensuring stable performance even in extreme marine operations.

To further enhance its durability, JINPAT performs rigorous testing, including a 9600VAC insulation withstand voltage test and an IP65 waterproof test before shipment. These precautions ensure the slip ring’s ability to resist moisture and dust, even in severe weather conditions such as storms and sea waves, thereby prolonging its service life and protecting its internal components.

Thanks to its outstanding performance and reliable quality, JINPAT’s offshore winch slip ring has become widely adopted in various offshore winch systems, establishing itself as an indispensable component in industries like marine engineering, marine scientific research, and fisheries. Its launch underscores JINPAT's commitment to technological innovation and quality improvement, while also contributing new energy to the global ocean exploration industry. By enhancing the efficiency and safety of offshore operations, this slip ring promotes the advancement of marine technology, paving the way for further progress in the field.