#Product Trends

Blister Inspection System

Blister Inspection System

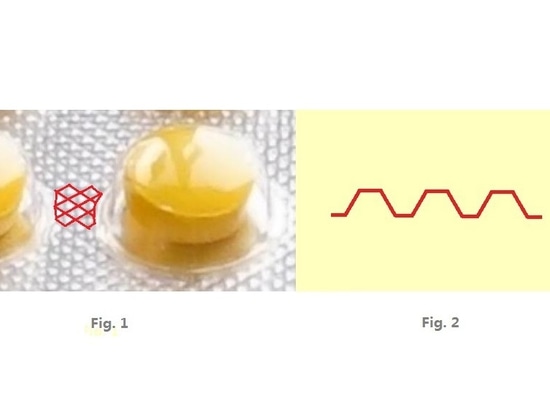

Quality assurance of packaged products is of critical importance in the pharmaceutical industry. Tablets packaged in blister packaging need to be inspected carefully for defects such as the wrong color, size, whether the tablets are broken or chipped and whether there are any empty pockets in the blister packaging itself.

Blister Inspection System can inspect all forms and types of blister products, such as tablets, hard/soft gelatin capsules, etc.

The requirements for the blister inspection system vary among different pharmaceutical companies, such as inspection of empty pockets only, or inspecting for crushed, powdered, fragments, wrong color, wrong size, etc, and inspection for products packaged in transparent film or opaque foil.

Here, we illustrate the blister inspection system for basic requirements such as inspection for empty pockets (missing product) and products packaged in transparent PVC film.

The camera is mounted inside a stainless steel canopy. The lens faces downward to the formed and products fed web, under the web installed a illuminant plate. When the blister machine is running, the illuminant plate emits light, and camera takes images of this area of the web. The images are then transferred to the system; Here, the blister packaging is inspected to see whether any empty pockets are present. For normally fed pockets, the light from the illuminant is blocked by tablets. But when an empty pocket appears, the light will shine through this pocket (because the PVC is transparent). This image is identified as an empty pocket. After being identified, the empty pocket moves forward, passes through the sealing station, the embossing station and the punching station. After punching, the faulty blister card (with empty pocket) will be rejected and fall into a container, the qualified blister cards is placed on the conveyer belt.

After being identified as an empty pocket, the web strokes that drive the empty pocket from the camera inspection to the punching station are referred to as “the number of strokes.”. The web distance between the camera and the punching station is certain. The operator needs to carefully calculate the number of strokes in advance and set it through machine’s HMI, if the data is incorrectly set, the rejection mechanism will reject wrong blister cards.