#Product Trends

Blister Packaging Machine DPP260K2

Blister Packaging Machine DPP260K2

The characteristics of Blister Packaging Machine DPP260K2:

·This Blister Packaging Machine can be packed separately to accommodate a lift having a 2.2m width, and delivered to the divided purification workshop.

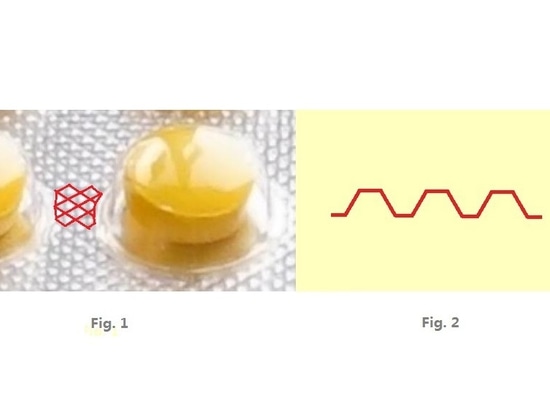

·It is suitable for plastic thermoforming and aluminum cold forming blister packaging.

·Adopts positioning formats for straightforward format changeover.

·Add an optional perforation station, to separate the perforation from the embossing station. Conventionally, perforation and embossing remain in one station, but this will influence the clarity of each.

·In the sealing station, when the machine stops, the heating sealing mould can rise up automatically, to prevent hot air from getting into the blister pockets, so that medicine effectiveness is preserved.

·Sealing pressure adopts the gas-hydraulic pressure cylinder, so the pressure can be set freely according to the sealing area (commonly a larger sealing area requires higher pressure).

The cylinder is placed under the sealing station to improve machine structure and gravity.

·Separation of drive and operating zones are in compliance with pharmaceutical GMP requirements.

·Material drag system adopts a precise servo motor to achieve stable, accurate running allowing blister length to be set freely.

·Can adopts whole-cover structure and safety-door according to customer requirement (optional).

·This machine can be custom-built to produce plastic thermoformed trays with maximum forming depth reaching 50mm.

See Our Products and Services in Action Contact Us for more details...

Main Technical Parameters:

Max. Speed: alu/alu 40 punches/min. alu/pvc 70 punches/min.

Max. Output: 240 blisters/min. (alu/pvc blister size 57×80mm)

Max. Forming Area: 245×152mm

Max Forming Depth: 12mm

Material: Max. width 260mm

Machine Power: 9.6kw

Machine Dimension: 4 stations: 4200×740×1700mm

5 stations: 4450×740×1700mm

Machine Weight: 4 stations: 1800kg

5 stations: 1950kg