#Industry News

Testing Brakes under Real Conditions

Maximum Safety thanks to Test Laboratories

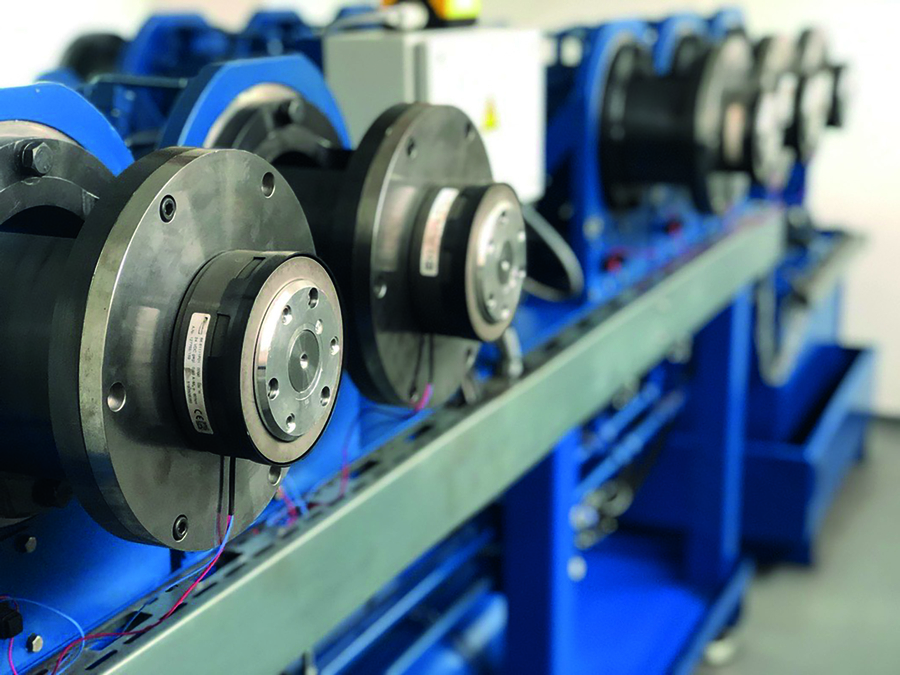

Kendrion operates test laboratories with top-class equipment in Villingen-Schwenningen and Aerzen, and an additional large-scale laboratory is currently being built in China. The many different test benches enable the testing of brakes in advance under all operating conditions that may be encountered in the field. Regardless of the relevant application, this ensures optimal safety for the customers.

“No matter what the subsequent usage conditions are, we are able to simulate them in our test laboratories,” Bernd Fürst from Kendrion points out. “This includes special loads as well as extreme temperatures and humidity.” The test laboratories are basically used for global quality assurance and to qualify customer projects, whereby the same processes are used at all locations. Among other things, the test benches allow us to determine the torques and switching times of brakes when exposed to temperatures from -60 °C to +180 °C and relative humidity from 10–98%. We can also simulate life cycles based on torque, speed, and the torsion angle. Even safety parameters B10 and B10d for safety-critical applications can be determined at up to 15 switching cycles. “We are also using the test laboratories for basic research, for example to try out new types of friction linings,” explains Philip Sewelies from Kendrion. “In this way, we are ready for new applications and can quickly respond to the requirements of our customers.” Speaking of flexibility: For customer-specific requirements, Kendrion builds dedicated test benches that enable the simulation of special operating conditions. This allows customers to take advantage of Kendrion’s know-how and shortens their time to market.

To maintain the state-of-the-art at all times, all test laboratories are continuously updated and supplemented if necessary. Currently, Kendrion is working on automating processes even further. This shortens the set-up effort and the testing time. “More automation means that we can carry out standard tests faster,” Philip Sewelies says in conclusion. “This gives our team more time to work on individual customer requests or development projects.”