#Product Trends

S300X - LIQ21 | LIQ11 Lynxter launches a new silicone 3D printer

Equipped with IDEX technology, the S300X - LIQ21 | LIQ11 is capable of printing materials such as silicone and PU with support, enabling complex shapes to be produced.

Additive manufacturing is rapidly gaining in popularity. It is increasingly affordable, easy to use and reliable! Yet a few pieces of the puzzle are still missing, restricting what users can do. The knowledge and experience in silicone 3D printing that we have acquired over the years, beginning on the S600D, has allowed us to announce a groundbreaking new solution for the 3D printing of elastomers: the S300X - LIQ21 | LIQ11.

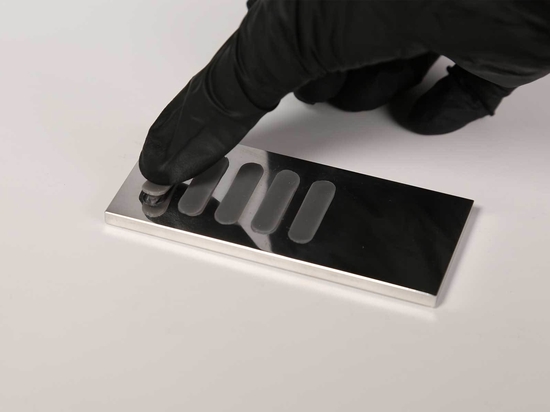

The S300X is the most powerful option on the market today for printing medical and industrial grade silicones and polyurethanes. Shapes that can’t be printed are now a thing of the past thanks to its integrated printed support technology.

A compact, reliable and sturdy industrial tool with an open philosophy, the S300X - LIQ21 | LIQ11 is the ideal machine for producing customized masking parts for post-processing (painting, sanding, plasma treatment etc.), dampers, seals, orthoses certified for skin-contact and textiles with additional functionality.

S300X - LIQ21 | LIQ11, the rapid response capabilities of 3D printing, are now available in industrial and medical grade silicone and polyurethane” Thomas Batigne, CEO of Lynxter.

3D SILICONE 3D PRINTING

Though this innovation, Lynxter is democratizing printing with silicone. A simplified, affordable and open solution designed for multiple applications: industrial (seals, masking, maintenance etc.), R&D (prototyping, material formulation, soft robotics) and medical (epitheses, protheses, orthopedics). In the medical field, silicone additive manufacturing makes it possible to produce custom-made devices without taking a manual impression or using a mold. It also allows hollowing and the variation of infill rates to render parts lighter or modify their properties (reduce hardness, add resistance, better damping, from anisotropy to the printed part etc).

The S300X can print a variety of materials including medical grade RTV2 silicone (5, 10, 25, 40 ShA) certified ISO 10993-05 for contact with skin, industrial grade RTV2 silicone (45shA) and polyurethane (from 50 to 85 ShA). These age-resistant silicones require no heavy post-processing and possess mechanical properties equivalent to those of injection molding.

Note that the arrival of the S300X coincides with the release of Lynxter’s own range of materials which include its industrial quality SIL001 silicone

Read More on lynxter.fr/en