#Industry News

CTS - COGGING TEST SYSTEM

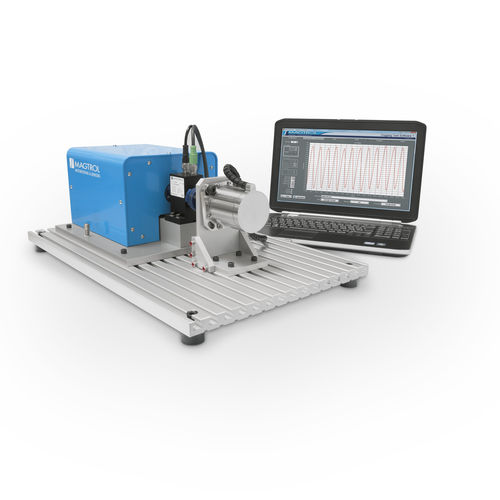

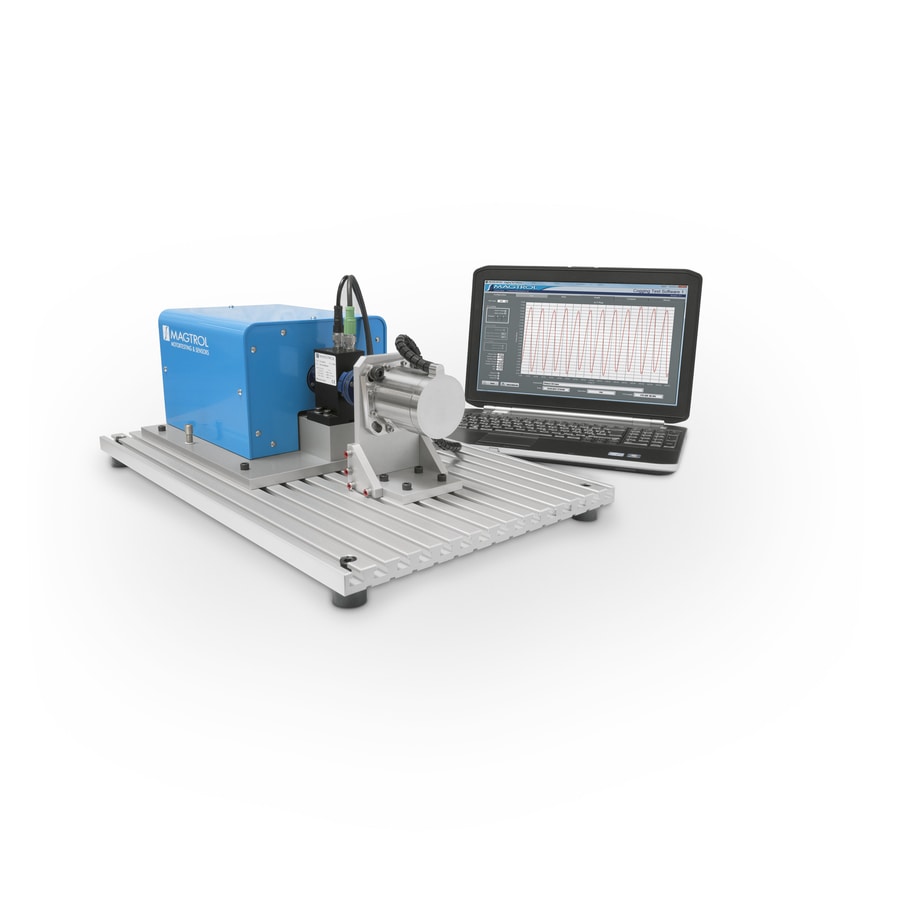

The drag torque or Detent Torque is an important parameter in permanent mag¬net (PM) motors, especially in a PM servo motor system. To measure this parameters, Magtrol introduced its 2nd generation of CTS COGGING TEST SYSTEM

The drag torque or Detent Torque is an important parameter in permanent mag¬net (PM) motors, especially in a PM servo motor system. Detent Torque of PM motors is composed of Cogging Torque and Friction Torque. The Cogging Torque is generated by attraction/interaction of the magnetic poles to the teeth (steel structure) within an un-energized motor. It is one of the most important parameters of permanent magnet motors, which causes torque ripple, vibration and noise.

To measure this parameters, Magtrol introduced its 2nd generation of CTS - COGGING TEST SYSTEM with the following system features:

- Measure of Detent Torque, Cogging Torque and Friction Torque

- Torque Detection < 1 mN·m

- Rated torque 50 / 100 / 200 mNm (other range available on demand).

- Accuracy 0.1% / 0.2% of rated torque ▪ Precise Angle Detection 5000 pulses/rev.

- Operating speed 1 to 10rpm ▪ Operating Direction CW / CCW ▪ USB Interface ▪ Executable Specific Cogging Test Software

- Peak Detection

- X-Y, Polar and FFT Graphs

- Multigraphs function with up to 5 curves comparison

- Data Acquisition and Storage in TXT (Export in CSV files possible)

The test System includes a precision geared motor, a TS torque sensor integrating a 5000 pulses encoder and security clutches to avoid system overload by mishandling when not in use. The geared motor drives the MUT (Motor Under Test) at low speed of 1 to 10rpm, while acquiring its cogging torque related to angle position. The torque measurement covers a range up to 200mN∙m (depending on the selected torque sensor) with an accuracy of ±0.1 mN∙m (for TS100 with 50mN∙m of nominal range). An executable software control the system realizing the measurement and data acquisition. It provides accurate peak-to-peak measurement of cogging torque and displays X-Y or polar graphs as well as FFT analysis. It allows the storage of the measured data enabling to compare performance graphs by overlaying up to 5 graphs. A cursor can be used to read accurate values from measurement points. Measured parameters can be saved under TXT. For better accuracy and function control, the software includes a 0 offset adjustment routine which check transducer signal over a complete turn (Test sample MUT not connected to the system).

As stand-alone system, the CTS only requires a 100-220VAC power. USB interface allows direct connection to the PC on which the software is installed. It is mounted on a PT-25 grooved base on which the motor fixture can be fitted. Vertical mounting bracket are available as an option, allowing to mount the system in vertical position, which is particularly recommended for very low measuring values. The system can easily be scaled up or down (50 / 100 ( 200 mNm), simply by replacing the TS torque sensor which is mounted in front of the unit. The software will recognize the torque sensor being in use and will automatically adapt its measuring range.

Need specific Motor Testing ? Do not hesitate to challenge us !