#Industry News

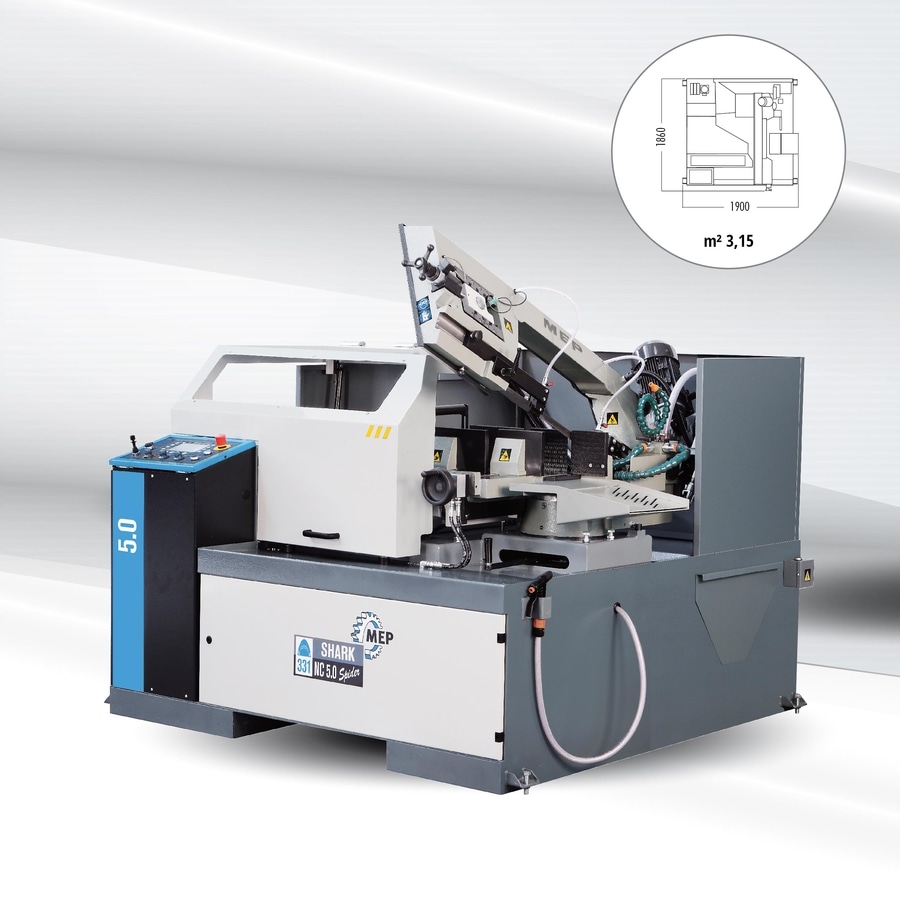

THE AUTOMATIC SAW WITH LARGE CAPACITIES, IN JUST 3,5sm !

SHARK 331 NC 5.0 spider, Electrohydraulic automatic band sawing machine which can also operate in semi-automatic cycle for cuts from 0° up to 60° left. Machine with compact dimensions.

SHARK 331 NC 5.0 spider, Electrohydraulic automatic band sawing machine which can also operate in semi-automatic cycle for cuts from 0° up to 60° left.

Machine with compact dimensions.

CNC machine with a new controller: MEP 50 with Windows “CE” based. This new PLC has been specifically designed by MEP for the automation of its range of products.

A FEW FEATURES:

– 7” touch screen display operator interface and push buttons for all functions of the sawing machine. It is simple and intuitive, it guarantees a reliable use and it controls all cutting parameters in real time.

– Console with all centralized controls, installed on a fixed pedestal in order that the operator can operate all programming and operating functions completely safe.

– Visualization and registration of alarms and events with the possibility to visualize the story of occurred events.

– Visualization and registration of alarms and events with the possibility to visualize the story of occurred events.

– Electronic inverter for the continuous adjustment of the band speed from 15 to 100 m/min.

– Latest generation hydraulic control unit, with high efficiency and low energy consumption.

– Bar feeder with recirculating balls screw/nut and stepper motor (feed in length in one stroke 600 mm, that can be repeated in order to cut any length).

– Feeding vice cover with safety limit switch in case the operator opens the cover during the cutting cycle.

– Cutting head and feeding vice positioning with joystick.

– Automatic acquisition of the actual starting point of the cut.

– Electronic transducer to visualize band tensioning.

– Automatic adaptive shearing stress control system with servovalve mounted directly on the cylinder.

– Continuos control of the blade rotation. In case the blade is jammed, automatically the machine will stop.

– Adjustable rollers for bundle cutting on one row.

– Adjustable guide to unload cut pieces.

– Extractable coolant tank with two electric pumps so as to lube-refrigerate band. The drawer to collect chips can be replaced with a motorized chip auger (OPTIONAL).

– Preset to be equipped with the spray mist system (OPTIONAL), as well as with the standard-delivered traditional lubrication with emulsible oil.

– Additional foot pedal with emergency stop (OPTIONAL).

– Wire chip brush for band cleaning.

– Emergency lamp with acoustic signal in case the machine is in a stand still situation.

– Machine arranged for handling with movement equipment.

– Bi-metal band for solids and sections.

– Service keys and instructions manual for maintenance and spare parts list in the language of use.