#Industry News

What is Metal Phase Analysis?

Metal Phase Analysis

Phase analysis is a crucial technique used in industries such as engineering, geology, and materials science to study a sample's phases, composition, surface characteristics, and thermal conditions. It can be conducted via several methods, including X-ray diffraction (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM), depending on the required outcomes. Metal phase analysis is vital for gaining information about specific metallic materials, which is then used to develop and improve them. This blog post provides more information on metal phase analysis and how it benefits specific industries.

Basics of Metal Phase Analysis

Metal phase analysis is required to characterize different phases in metallic materials. A phase is a section of a material, such as an alloy, that is chemically or physically homogenous throughout. The phase of a material will have its own chemical, electrical, mechanical and physical properties and can be individually characterized, offering valuable information about it and the material it is part of.

Characterizing metal phases can be conducted with XRD, SEM and TEM, which enable researchers to look more closely at the metal phases' chemical composition, crystal structure and microstructure. Once this information has been obtained, it can be used to enhance the material’s properties and ensure it is used effectively in specific applications.

X-ray Diffraction

XRD is used to analyze the composition and crystal structure of metal phases within a sample. The process works by focusing a beam of X-rays onto the sample, which produces a diffraction pattern. The diffraction pattern shows the crystal structure of the phases, which can then be analyzed for further information.

Scanning Electron Microscopy

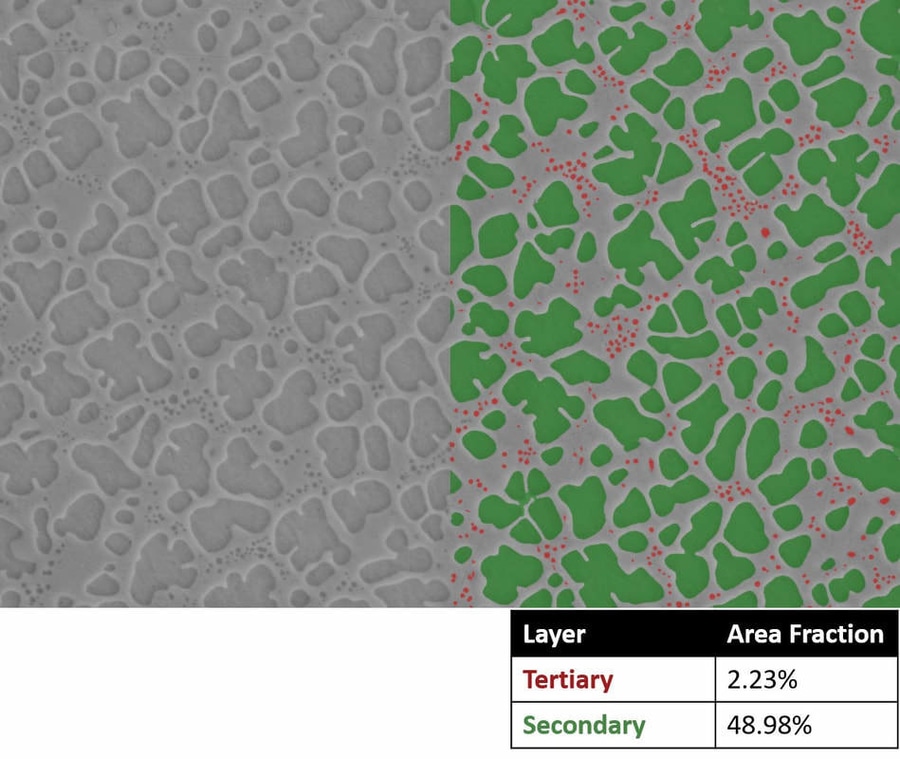

In SEM, a beam of electrons is scanned over a metal sample and detects scattered electrons. Once the electrons are identified, an image is produced that provides information about the microstructure and morphology of metal phases in a sample.

Transmission Electron Microscopy

TEM is another method of phase analysis. A thin slice of metal is extracted as a sample, and a beam of electrons is passed through it. An image is created that shows the crystal structure and morphology of the phases within a sample and also provides information on distribution and size.

Each of these techniques offers crucial information about a sample, which benefits manufacturers and scientists alike in their respective fields. If a more detailed analysis is required, other techniques can be used in combination with XRF, SEM or TEM to provide a more comprehensive understanding of a sample.

Applications of Metal Phase Analysis

Metal phase analysis is used in a variety of fields, such as metallurgy, mining, and materials science, as it provides invaluable insight into a sample’s properties and structures. Having such detailed information about a sample enables researchers to develop or enhance materials for specific applications. This section will also briefly mention the benefits of metal phase analysis in its applications.

Materials development

Metal phase analysis is frequently used in materials development, as the techniques mentioned enable scientists to analyze the composition and structures of metallic materials. With that information, the properties of metallic materials can be enhanced for specific applications, which includes corrosion resistance, durability and strength.

Failure analysis

When metal components break or are damaged, metal phase analysis can be used to gain deeper insight into what went wrong. Using XRD, SEM or TEM, researchers can look at the internal structure of a sample to determine whether failure was a result of a manufacturing error, environmental factors or something else.

Quality control

The processes used for metal phase analysis can determine whether a material meets compliance and quality standards. This is conducted by studying a metallic component's composition and internal structure, from which manufacturers can identify specific properties such as hardness and strength.

Environmental monitoring

Metal phase analysis identifies and monitors pollutants and traces minerals in an environment, including water and soil samples. Researchers can study the distribution and composition of metal phases to look at the sources of contamination and understand the environmental impact.

As you can see, metal phase analysis has many applications. By understanding the composition and structures of metal phases in a metallic material, researchers can look at how to develop new materials, monitor pollution and conduct quality control measures.

MIPAR Software and Phase Analysis

MIPAR is a world-leading algorithm development and image analysis software company specializing in life and materials sciences and offers products to a wide range of other industries. We provide products that eliminate the margin for error through automation for phase analysis, grain size measurement, and particle studies.