#Industry News

How is Grain Size Measured?

Grain Size Analysis

Grain size is a fundamental property of metallic materials that enormously impacts their mechanical, physical, and chemical properties. Grain structure analysis is commonly conducted in material laboratories, and the complex processes used must meet the research and industry requirements. Because grains are so intricate, precisely analyzing them provides valuable information about their structures and properties, which leads to gaining further knowledge on their practical applications.

Hence, grain size measurement is a critical step in material characterization for research and industry purposes. This blog post delves into the basics of grain structure analysis and briefly discusses standard test methods used for grain size determination. It will also discuss the benefits of automating grain size measurement using advanced software.

Grain Size Measurement Methods

Materials science is a multidisciplinary field that combines engineering methods with chemistry and physics to research and develop materials. Materials science analysis is the study of a material’s chemical and physical properties to identify flaws and strengths, develop new materials, or improve existing ones for specific applications.

Indirect measurement covers a range of techniques that infer grain size from some related property, such as electrical resistivity of magnetic permeability. Grain size can be calculated using empirical equations that relate said properties to the average grain size.

Standard Test Methods for Determining Average Grain Size

The American Society for Testing and Materials (ASTM) has developed several standard test methods for determining the average grain size of metals and alloys (i.e. ASTM E112 and ASTM E1382).

- ASTM E112 method involves the manual counting of grains using an optical microscope and the calculation of the average grain size using a statistical method. These include the comparison procedure, planimetric procedure, and intercept procedure.

- ASTM E1382 method involves the measurement of the magnetic properties of the material, such as coercivity or remanence, and calculating the average grain size using an empirical equation. This also covers the use of semi- and fully-automated image analysis.

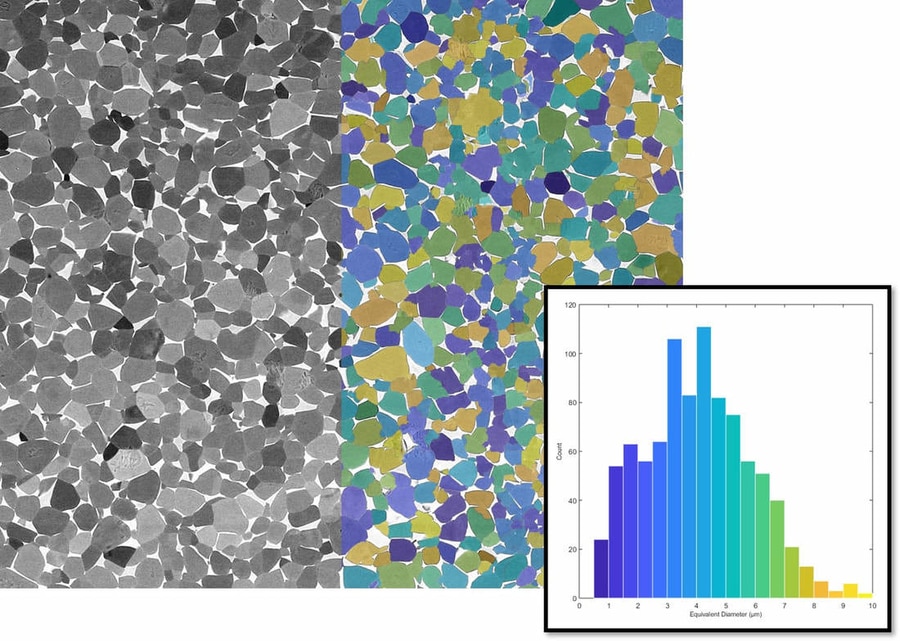

The advantages of measuring grain sizes with the correct image processing methods allow non-destructive, accurate, and objective grain-size analysis and distribution. Microstructures of materials can vary and, therefore, must be analyzed for researchers to understand what properties are present and what applications the structures are most suitable for.

How to Automate Grain Size Measurement

Automated grain size measurement is increasingly prevalent in the material science industry due to its efficiency and accuracy. We have developed advanced grain measurement software that benefits researchers and industry professionals. Our software provides fully automated grain size solutions, the ability to analyze micrographs without continuous reference to a microscope, and the ability to run data samples in batch sets. Additional benefits of MIPAR's automated grain structure analysis systems include generating statistics and comprehensive reports to easily and efficiently share data across research and industry networks.

Our software uses cutting-edge deep learning technology to simplify grain structure analysis into three discrete steps: trace, train, and apply. The software's intuitive user interface solves challenges such as low contrast and noise in grain imaging and detects grains while ignoring twins, all in a matter of seconds. This software applies to a range of advanced and commonplace materials, including titanium, steel, copper, aluminum, and ceramics.

Need Help Automating Grain Size Analysis?

Automated detection and measurement of grain sizes, microstructure insights, and error-free sample batch processing that exceeds the ASTM E112 grain size requirements. The microstructure insights available through MIPAR’s image analysis software include the diameter, shape, and size of grains, which can be collected through limitless image samples.

References

1. https://www.sciencedirect.com/science/article/pii/S0264127517311620