#Industry News

Using Thermal Imaging in Regular Inspection

Thermal Imaging in Regular Inspection

The Need for Safety on Railways

With speeds of railway vehicles increasing, reaching current maximums of up to 350km/h, it is becoming increasingly important to ensure the safety of railway vehicles. Components of railway systems are hugely important to this, with efficient maintenance directly impacting the safety of the railway. Thermal imaging has become a cornerstone of safety on the railway and this article will detail its applications.

Laser Diffraction

Laser diffraction particle analysis method measures the particle size distribution by quantifying the angular variation in intensity of light scattered whilst a laser beam passes through a particulate sample that has been dispersed.

Laser diffraction is advantageous as a method of particle analysis as it is easy to operate, has a broad test range and has a high level of precision and repeatability. However, the instrument used for laser diffraction particle analysis is extremely expensive and the method’s results depends on the distribution pattern.

Thermal Imaging Cameras to Aid Safety

Traditionally, CCTV has been the main form of security for railways, however although CCTV cameras are effective, reliable tools for video analysis, they have a number of limitations. CCTV can be hindered by over-exposure from the sun and recording in the dark requires additional light sources.

Thermal imaging cameras are not subject to the same defects as CCTV as they are not hindered by environmental changes such as fog, darkness, or smoke. Thermal imaging creates images based on minute variations in heat radiation, allowing for operators to detect any potential risk during the night or adverse weather conditions.

Thermal Imaging for People Detection

Railway services are subject to the risk of the public being present on tracks. People may fall on to the tracks, walk through tunnels or walking on the railway and this can be detected quickly by thermal imaging. Small animals or passing trains will not impact this or trigger concern from railway managers.

Obstacle Detection with Thermal Imaging

Rail collisions can be prevented by the use of thermal imaging to detect vehicles which are stuck on a level crossing or any other obstacle on the train track. These types of collisions can cause serious harm to both passengers and rail equipment such as trains and tracks. By detecting a stationary object on the tracks which is blocking the passage for an oncoming train, a warning signal can be communicated to a railway operations center.

Workstation operators can view the threat and take the appropriate action, such as warning the approaching train/tram through rail signals, warning lights or direct communication with the driver.

Using Thermal Imaging for Fire Detection

Thermal imaging cameras can measure the temperature of any object that they can see which means they can detect fires at an early stage. Traditional smoke detectors have to make contact with smoke particles before raising an alarm, meaning a fire often has to be relatively advanced to be registered. Using thermal imaging means that fires can be detected within seconds and will not be triggered by cigarette smoke. This means that rail operators are able to identify fires and respond appropriately and in a timely manner.

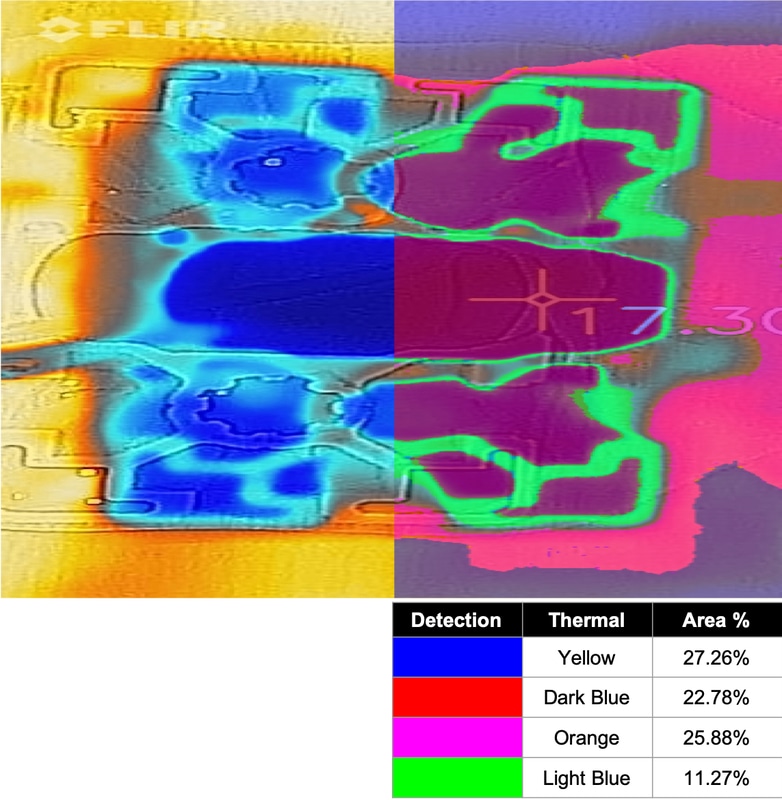

Using Thermal Imaging for Railway Inspection

Rail surface defects have a substantial impact on the safety of railway systems. Currently, human inspection and rail vehicle inspection are the main methods of detecting rail surface defects. However, these methods have downsides such as low efficiency and high cost.

Drone imaging is at the forefront of innovation in railway inspection, focusing on image enhancement and defect segmentation. Thermal imaging is used when the rail surface defects and backgrounds are highlighted under varying degrees of sunlight intensity.