#Product Trends

conveyor belt FB 14, transported parts to 10 kg at belt speeds up to 45 m / min.

Conveyor belt with belt widths from 35 mm to 400

conveyor belt FB 14, transported parts to 10 kg at belt speeds up to 45 m / min.

Conveyor belt with belt widths from 35 mm to 400

Brushless DC drive and robust worm gear for low maintenance operation

The MM Engineering Conveyor Series FB10 convince through internal brushless DC drives with integrated motor controller. These conveyor belts come in a variety of industries in the transport of small parts and bulk, for example, under punches, with drying and sorting lines or parts inspection by camera.

New to Motek 2016 presents MM Engineering, the FB14, a variant use external, stronger-performance 24 V DC motor with worm gear. This system is designed for heavier, larger cargo up to 10 kg and higher belt speeds up to 45 m / min.

For automated processes, the low wear brushless 24 V DC motor with an integrated motor controller for speed control features via 0 - 10 V signal. Optionally, the user can set the speed via a potentiometer on site.

Other features include the on-off circuit, short-circuit braking and changing direction. On pulse output are 2 pulses per motor revolution to disposal. Together with the robust worm gear almost maintenance-free operation is possible.

The FB14 is available with belt widths from 35 mm to 400 mm and lengths up to 4000 mm. On the non-driven side can be a rolling knife edge with 15 mm diameter installed, for a careful, step-free transition to the next conveyor. Numerous belt materials and finishing are possible, for example, smooth or with transverse and longitudinal profiles and sidewalls. The belt pad is stable executed with 2 mm stainless steel sheets.

MM Engineering manufactures the base frame of the conveyor belt made of aluminum profiles (Bosch system) in custom length and width, and lays out the system for individual belt speeds and motor assembly.

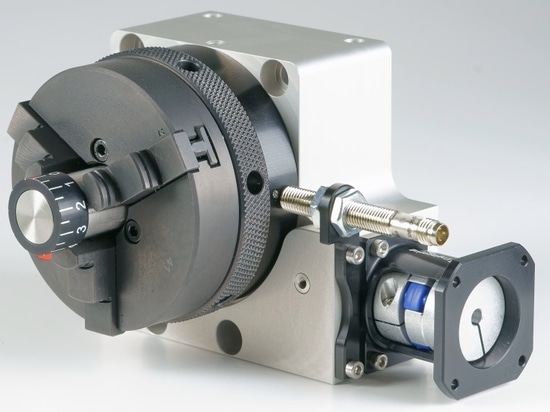

Short Portrait MM Engineering GmbH

MM Engineering based in Eglharting near Munich, is a specialist in hand-adjustable and motorized positioning systems as linear, rotary, cross and lift tables. The modular system allows a variety of combinations. Another product segment includes the compressed air-and vacuum-operated cylinder for lifting and placing of parts. The very compact units can be easily integrated into existing systems. Interfering edges Free conveyors with internal drives round off the current portfolio. In-house development and manufacturing "Made in Germany" provide clever, application-specific solutions in high precision and allow short delivery times. Currently, the privately owned firm supplies its products in sectors such as engineering, automotive industry, medical technology, optical industry, precision engineering, woodworking industry, plastics industry, paper industry, glass industry.