#Product Trends

How does Kevlar braided sleeve compare to other types of braided sleeves?

How does Kevlar fiber sleeve compare to other types of braided sleeves?

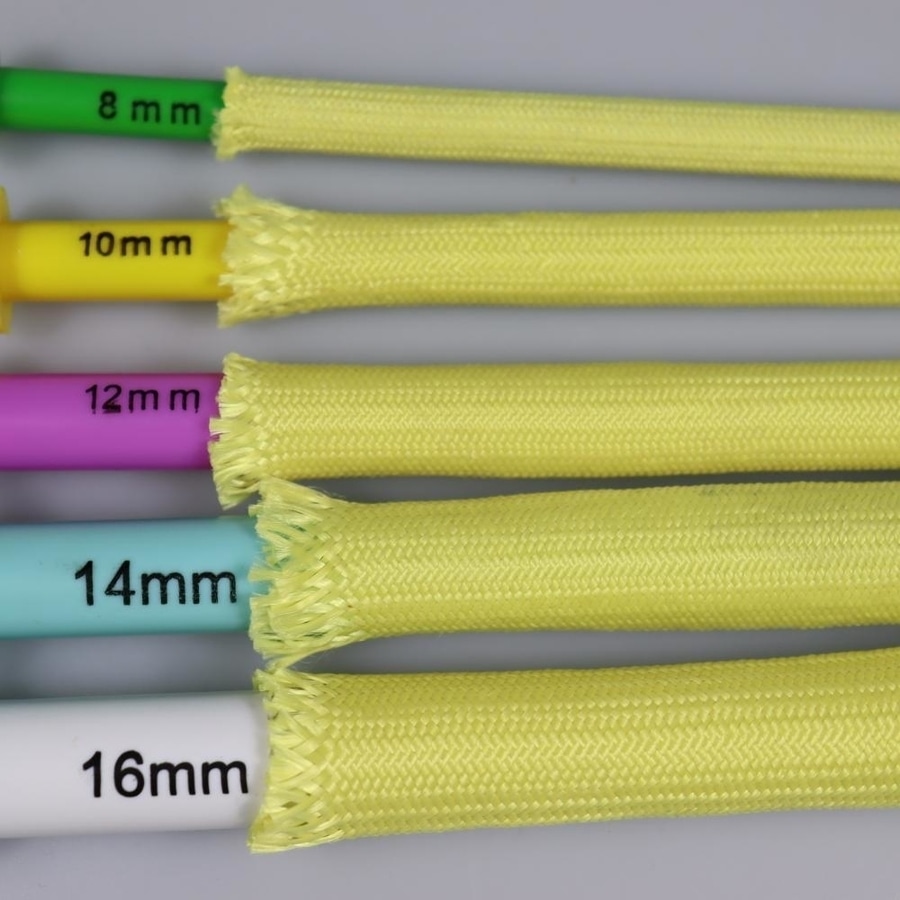

Compared to other types of braided sleeves, Kevlar braided sleeve has several unique properties that make it a popular choice for many applications.

Firstly, Kevlar braided sleeve is highly resistant to abrasion, impact, and heat, making it an ideal choice for protecting components in harsh environments. In contrast, other types of braided sleeves may not offer the same level of protection against these types of damage.

Secondly, Kevlar braided sleeve is highly flexible, which makes it easy to install and use in a wide range of applications. Other types of braided sleeves may be less flexible, which can make them more difficult to install and use.

Thirdly, Kevlar braided sleeve is resistant to a wide range of chemicals, which makes it an excellent choice for use in harsh chemical environments. Other types of braided sleeves may not offer the same level of chemical resistance.

Finally, Kevlar braided sleeve is extremely durable and long-lasting, which makes it a cost-effective solution for protecting components from damage and wear. Other types of braided sleeves may not be as durable or long-lasting, which can result in more frequent replacements and higher costs over time.

Overall, while other types of braided sleeves may have their own unique properties and advantages, Kevlar braided sleeve is a popular choice for many applications due to its high level of protection, flexibility, chemical resistance, and durability.