#Product Trends

Black Silicone Heat Sleeve: Key to Efficient Electrical Engineering

Black Silicone Heat Sleeve

In the world of electrical engineering, ensuring the reliability and efficiency of electrical systems is crucial. The efficient management of heat in electronic components is a significant challenge, especially in high-temperature environments. Black silicone heat sleeves have emerged as a vital solution, playing a key role in achieving efficient electrical engineering. In this article, we explore the importance of black silicone heat sleeves and their contribution to the efficiency of electrical systems.

1. Understanding Black Silicone Heat Sleeve

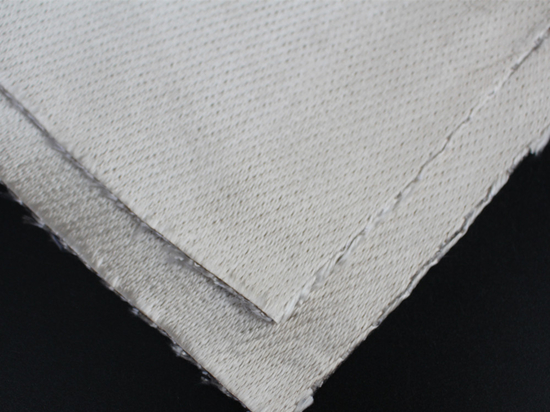

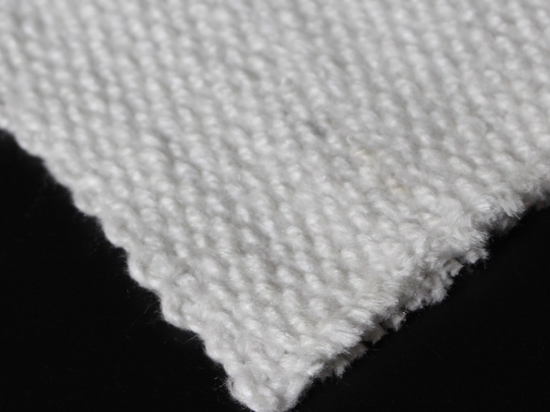

Black silicone heat sleeves are crafted from premium-grade silicone rubber, reinforced with glass fibers. This unique combination provides them with exceptional thermal resistance, making them ideal for applications that involve exposure to high temperatures. Designed to endure temperatures of up to 200°C, black silicone heat sleeves act as a protective barrier, shielding sensitive electronic components from the adverse effects of heat.

2. Heat Management for Electronics

In electrical engineering, the efficient management of heat is critical to the performance and reliability of electronic components. Black silicone heat sleeves play a crucial role in dissipating heat generated during the operation of electrical systems. By effectively insulating and isolating heat, these sleeves prevent thermal stress and ensure the optimal functioning of electronic components.

3. Preventing Overheating Issues

One of the primary challenges in electrical engineering is dealing with overheating issues. When electronic components are exposed to high temperatures, their performance can be compromised, leading to reduced efficiency and potential breakdowns. Black silicone heat sleeves offer a reliable solution by dissipating excess heat and maintaining a stable operating temperature, preventing overheating and prolonging the lifespan of electrical systems.

4. Versatile Applications in Electrical Engineering

Black silicone heat sleeves find versatile applications in electrical engineering. They are extensively used to protect wires, cables, and connectors in various electrical systems, such as motors, transformers, and power distribution units. By shielding these critical components from heat-related damage, black silicone heat sleeves ensure the efficiency and safety of electrical equipment.

5. Contribution to Energy Efficiency

Efficient heat management is directly linked to energy efficiency in electrical engineering. When electronic components operate within their optimal temperature range, they consume less power and generate less waste heat. Black silicone heat sleeves contribute to overall energy efficiency by maintaining the desired temperature levels, reducing energy consumption, and minimizing thermal losses.

6. Reliability and Longevity

Reliability is paramount in electrical engineering applications. Black silicone heat sleeves enhance the reliability and longevity of electrical systems by safeguarding components from the detrimental effects of heat. Their durable construction and superior thermal resistance ensure that critical electronic parts can operate consistently and reliably, even under demanding conditions.

Conclusion

Black silicone heat sleeves play a pivotal role in achieving efficient electrical engineering. With their outstanding heat management capabilities, they protect electronic components from overheating, contributing to improved performance, energy efficiency, and reliability of electrical systems. From motors to power distribution units, black silicone heat sleeves stand as a key solution in the quest for efficient and dependable electrical engineering. Embracing these advanced heat protection solutions can optimize the operation of electrical systems, ensuring their successful performance in various applications.