#Product Trends

Silicone Coated Silica Fabric: Heavy-Duty Protection for Demanding Applications

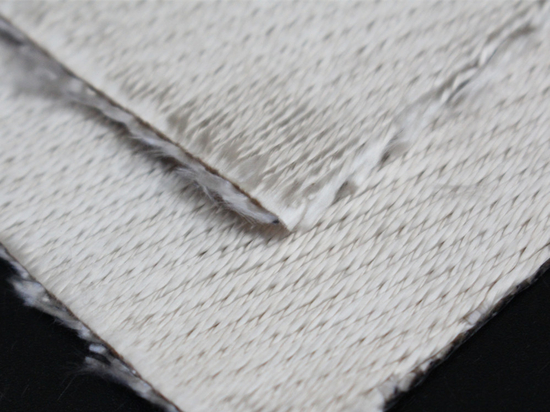

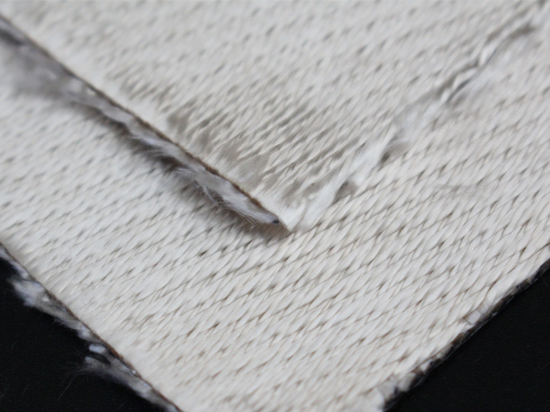

Silicone Coated Silica Fabric

Silicone coated silica fabric is an advanced protective material designed to withstand the most demanding industrial environments. This innovative fabric features a high-strength silica base that is coated on one side with silicone rubber, providing superior heat resistance and durability compared to conventional welding fabrics. Its unique composition makes it an ideal choice for heavy-duty applications where personnel and equipment require robust protection against extreme temperatures and abrasive conditions.

One of the standout features of silicone coated silica fabric is its impressive temperature capability. The silica base fabric can endure high temperatures, making it suitable for applications that involve direct exposure to flames, molten metal, or other heat-generating processes. With the added silicone coating, the fabric maintains its integrity even in the harshest conditions, ensuring reliable performance for extended periods. This capability is essential for industries such as welding, metalworking, and foundries, where safety and protection are paramount.

In addition to its thermal resistance, silicone coated silica fabric exhibits outstanding abrasion resistance. This property is crucial for environments where equipment and personnel are at risk of contact with sharp edges, rough surfaces, or other abrasive materials. The durability of the silicone coating enhances the fabric's ability to withstand wear and tear, reducing the frequency of replacements and maintenance costs. This longevity translates to improved safety and efficiency for businesses, allowing operations to continue without interruption.

Silicone coated silica fabric is highly versatile and can be used in a wide range of applications. It is commonly employed in the production of welding blankets, shields, and curtains, providing effective protection against sparks, spatter, and heat during welding operations. Additionally, this fabric is ideal for use in protective covers, heat shields, and insulation applications, ensuring that personnel and equipment remain safe from thermal hazards.

Another significant advantage of silicone coated silica fabric is its ease of use. The lightweight and flexible nature of the material allows for easy handling, cutting, and sewing. This feature makes it possible to create custom-sized protective gear tailored to specific requirements, ensuring a perfect fit for any application. The fabric's compatibility with various sewing techniques allows manufacturers to produce high-quality protective products quickly and efficiently.

Moreover, the silicone coating enhances the fabric's resistance to water, oils, and chemicals, making it suitable for use in environments where exposure to these substances is a concern. This additional protection ensures that the fabric retains its functionality and appearance over time, further contributing to its long-lasting performance.

In conclusion, silicone coated silica fabric is a premium choice for industries requiring heavy-duty protection against heat, abrasion, and chemical exposure. Its unique combination of high-strength silica and silicone rubber provides unparalleled performance, making it suitable for welding applications, insulation, and protective coverings. By selecting silicone coated silica fabric, businesses can enhance safety, reduce operational downtime, and improve the longevity of their equipment, all while ensuring the protection of their personnel in the most challenging environments.