#Product Trends

What is Silicone Coated Fiberglass Welding Blanket?

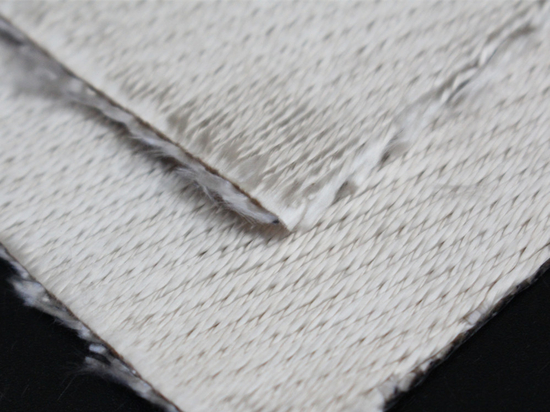

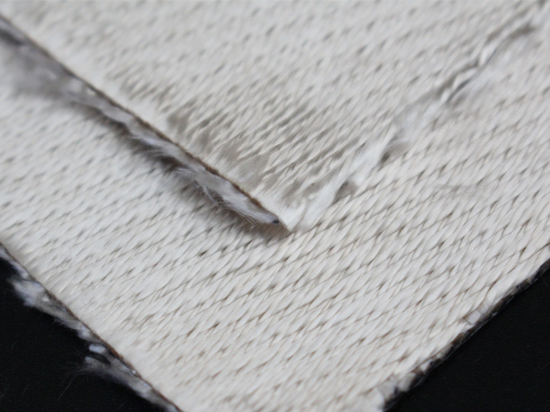

Silicone Coated Fiberglass Welding Blanket

The Silicone Coated Fiberglass Welding Blanket is a specialized protective fabric designed to provide excellent heat resistance and safeguard against sparks, spatter, and molten metal in welding and metalworking environments. Here’s an overview of its features and applications:

Overview

Material Composition: This blanket is made from fiberglass, which is coated with silicone. The silicone coating enhances the fiberglass’s inherent heat resistance, making it suitable for high-temperature applications.

Key Features

High-Temperature Resistance: Capable of withstanding temperatures up to 1,000°F (540°C) or more, the silicone coating provides superior protection against extreme heat generated during welding and cutting operations.

Flame Retardant: The silicone coating offers flame-resistant properties, helping to prevent ignition and reduce the risk of fire hazards in welding environments.

Durability: The fiberglass base provides strength and resistance to abrasion, ensuring a long lifespan in demanding industrial settings.

Water and Chemical Resistant: The silicone coating also makes the blanket resistant to water and many chemicals, further protecting it from damage in various environments.

Lightweight and Flexible: Easy to handle and maneuver, the blanket can be positioned around equipment and workpieces without adding significant bulk.

Applications

Welding: Protects workers, equipment, and surrounding areas from sparks, spatter, and heat during various welding processes.

Metal Fabrication: Ideal for use in workshops, the blanket creates a safe working environment by minimizing the risk of fire and heat damage.

Automotive and Aerospace: Used in industries where high-heat tasks are common, providing reliable protection for sensitive components.