#Product Trends

Why is Silicone Coated Fiberglass Sleeve the Best Choice for Protecting Cables in Harsh Environments?

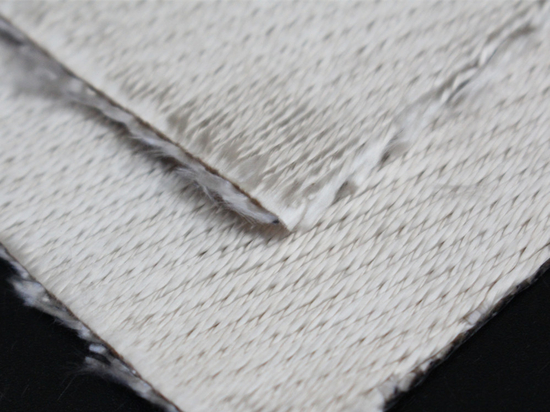

Silicone Coated Fiberglass Sleeve

In today’s industrial landscape, cables are often exposed to challenging conditions, including extreme temperatures, moisture, chemicals, and physical abrasion. To ensure optimal performance and longevity, selecting the right protective material is essential. Among the various options available, silicone coated fiberglass sleeves have emerged as the best choice for protecting cables in harsh environments. This article explores the key features that make silicone coated fiberglass sleeves an indispensable asset for cable protection.

1. Exceptional Temperature Resistance

One of the standout features of silicone coated fiberglass sleeves is their remarkable ability to withstand high temperatures. These sleeves can typically endure temperatures ranging from -100°F (-73°C) to +500°F (+260°C), making them suitable for a wide range of applications, including automotive, aerospace, and industrial machinery. This exceptional heat resistance prevents damage to cables and ensures that they continue to function efficiently, even in extreme conditions.

2. Superior Abrasion and Tear Resistance

Silicone coated fiberglass sleeves are designed to protect against physical wear and tear. The robust fiberglass base provides inherent strength, while the silicone coating enhances abrasion resistance, making these sleeves ideal for environments where cables may be subject to friction or impact. By using silicone coated fiberglass sleeves, businesses can significantly reduce the risk of cable damage, prolonging their lifespan and reducing maintenance costs.

3. Moisture and Chemical Resistance

Exposure to moisture and chemicals can be detrimental to cables, leading to electrical failures and safety hazards. Silicone coated fiberglass sleeves offer excellent resistance to water, oils, solvents, and various chemicals. This protective barrier not only prevents moisture ingress but also safeguards cables from corrosive substances, ensuring reliable performance in environments such as chemical plants, marine applications, and outdoor settings.

4. Lightweight and Flexible Design

Despite their robust protective qualities, silicone coated fiberglass sleeves are lightweight and flexible. This design makes them easy to install and maneuver around cables, ensuring a snug fit without adding unnecessary bulk. The flexibility also allows these sleeves to conform to various shapes and sizes, providing comprehensive coverage and protection for a wide range of cable types.

5. Electrical Insulation Properties

In addition to physical protection, silicone coated fiberglass sleeves provide excellent electrical insulation. This property is crucial in preventing short circuits and electrical failures in high-voltage applications. By using silicone coated fiberglass sleeves, businesses can enhance the safety of their operations and reduce the risk of electrical hazards.

6. Versatile Applications

The versatility of silicone coated fiberglass sleeves makes them suitable for various applications across multiple industries. From automotive wiring harnesses to industrial machinery and marine equipment, these sleeves can be used in any scenario where cables require robust protection. Their adaptability ensures that companies can rely on a single product to meet various cable protection needs.

7. Cost-Effective Solution

Investing in silicone coated fiberglass sleeves is a strategic decision for businesses looking to improve their operational efficiency. By preventing cable damage and minimizing maintenance needs, these sleeves offer a cost-effective solution for protecting valuable assets. The long-lasting nature of silicone coated fiberglass sleeves translates to fewer replacements and repairs, allowing companies to allocate resources more effectively.