#Product Trends

What Makes Basalt Fiber Sleeve a Top Choice for Extreme Temperature and Mechanical Stress Applications?

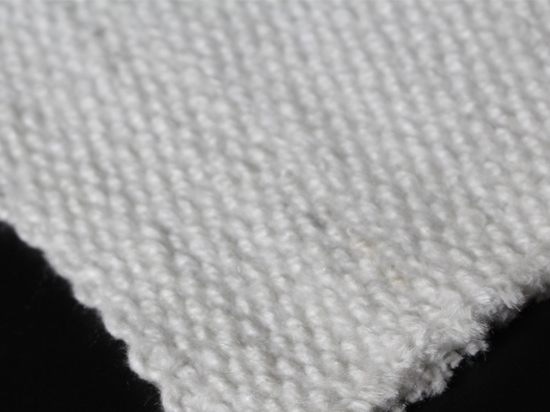

Basalt Fiber Sleeve

In the demanding landscape of industrial applications, where extreme temperatures and mechanical stress are common, selecting the right protective materials is crucial. Basalt fiber sleeves have emerged as a leading choice for engineers and manufacturers looking to safeguard critical components. This article explores the key attributes that make basalt fiber sleeves an optimal solution for applications exposed to harsh conditions.

1. Superior Thermal Stability

Basalt fiber is renowned for its outstanding thermal stability, withstanding temperatures up to 1,000°C (1,832°F) without losing integrity. This exceptional heat resistance is vital for applications in industries such as automotive, aerospace, and oil and gas, where components are often exposed to extreme heat. By using basalt fiber sleeves, operators can effectively protect sensitive cables, hoses, and wires from heat damage, ensuring reliable performance in high-temperature environments.

2. High Mechanical Strength

Basalt fiber sleeves exhibit impressive mechanical strength, making them highly resistant to deformation, tearing, and impact. This strength is critical in environments where mechanical stress is prevalent, such as manufacturing and construction. The robust nature of basalt fibers helps maintain the structural integrity of wrapped components, providing an additional layer of protection against wear and tear, abrasion, and other mechanical challenges.

3. Lightweight Yet Durable

One of the most appealing aspects of basalt fiber sleeves is their lightweight composition. Despite their durability, these sleeves do not add significant weight to the components they protect, making them easy to handle and install. This lightweight quality is particularly advantageous in applications where space is limited or weight reduction is essential, such as in aerospace engineering. The combination of low weight and high durability ensures that basalt fiber sleeves enhance rather than hinder overall system performance.

4. Excellent Chemical Resistance

Basalt fiber exhibits impressive resistance to a wide array of chemicals, including acids, alkalis, and solvents. This property is essential in environments where exposure to harsh chemicals is a concern. By using basalt fiber sleeves, operators can protect sensitive components from corrosive substances, reducing the risk of degradation and failure. The chemical resistance of basalt fibers extends the lifespan of the equipment, contributing to lower maintenance costs and increased reliability.

5. Environmentally Friendly Material

Basalt fibers are derived from natural volcanic rock, making them a sustainable and environmentally friendly option. The production process is energy-efficient and generates minimal waste, aligning with the growing emphasis on sustainability in industry. By choosing basalt fiber sleeves, companies can not only protect their equipment but also contribute to eco-friendly practices, appealing to environmentally conscious consumers and stakeholders.

6. Versatility Across Applications

The versatility of basalt fiber sleeves is another key factor in their popularity. They can be customized for a wide range of applications, from high-performance automotive exhaust systems to industrial machinery and aerospace components. This adaptability allows manufacturers to implement basalt fiber sleeves in various contexts, ensuring consistent thermal and mechanical protection regardless of the specific demands of the application.

7. Cost-Effective Long-Term Solution

While the upfront cost of basalt fiber sleeves may be higher compared to some alternatives, their long-term benefits justify the investment. The durability and resilience of basalt fibers lead to reduced maintenance and replacement expenses over time. By minimizing the risk of heat damage and mechanical failure, basalt fiber sleeves contribute to overall cost savings and operational efficiency.