#Product Trends

What is solder heat shield?

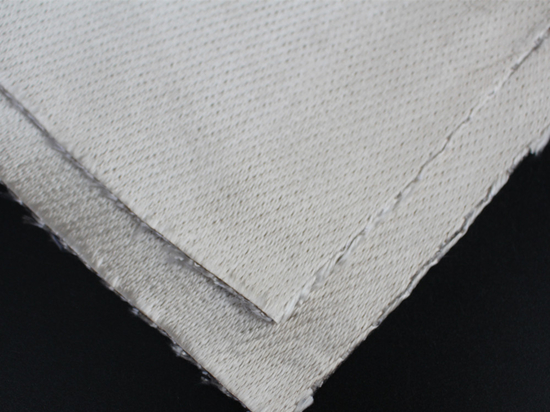

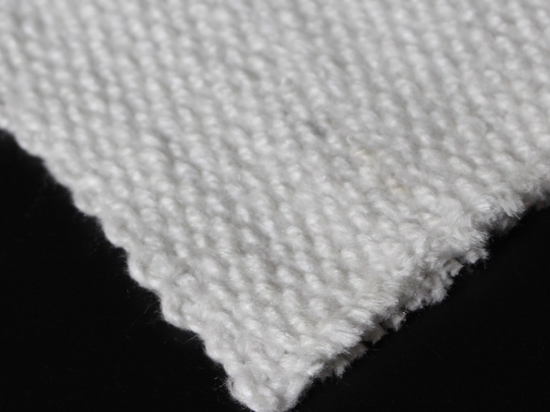

solder heat shield

A solder heat shield is a protective material used to shield sensitive components from heat damage during soldering or other high-temperature processes. It is typically used in electronics assembly, automotive, and industrial applications where soldering involves significant heat, which could potentially damage nearby components, wiring, or surfaces.

Here’s how a solder heat shield works and its key features:

Function:

Thermal Protection: The shield acts as a barrier to prevent heat from spreading to sensitive parts, such as nearby wires, plastic components, or circuit boards.

Heat Reflection or Absorption: Depending on the material, it can either reflect the heat away from the protected areas or absorb the heat to limit its impact.

Prevents Burns and Damage: It safeguards components from being overheated during the soldering process, which could cause failure or degradation.

Materials:

Solder heat shields are typically made from materials that are heat-resistant and provide insulation, such as:

Aluminized Fiberglass: Known for its ability to reflect heat while being durable and flexible.

Ceramic Fiber: Often used for high-temperature applications due to its excellent thermal resistance.

Silicone-Coated Fabrics: These can resist heat and are often flexible and easy to work with.

Kapton or Mylar Films: These can provide a thin, flexible shield that protects against heat during soldering.

Applications:

Electronics Assembly: Used to protect sensitive components, like semiconductors, capacitors, and connectors, during soldering.

Automotive: Used to shield sensitive parts like wiring or rubber hoses from heat when working with exhaust systems or engine components.

Industrial Welding and Soldering: Protects other parts of machinery or equipment from excess heat during processes like welding or soldering.

Benefits:

Prevents Component Damage: Helps avoid overheating sensitive components, which can lead to failure.

Increases Efficiency: Allows for more precise soldering and faster processes by protecting components in the surrounding area.

Cost-Effective Protection: Prevents costly damage and repairs by offering affordable heat protection during high-temperature processes.

Solder heat shields are essential for ensuring both safety and the longevity of components in heat-intensive environments.