#Product Trends

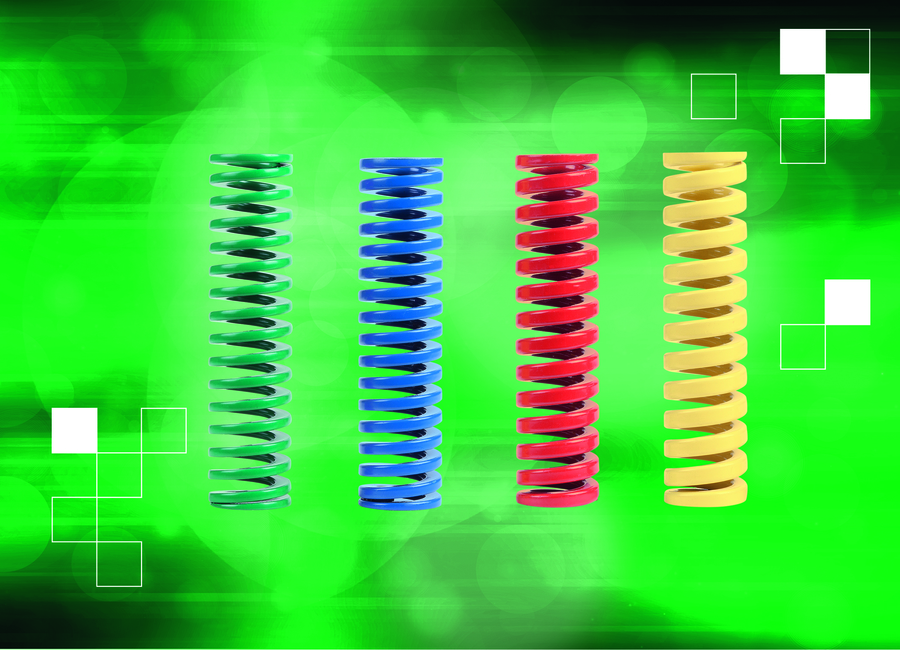

norelem has introduced high quality compression springs into its portfolio

Designed for extreme alternating and permanent loads as well as high temperatures

Used in tool making machine construction or fixtures, the new helical springs from norelem are higly versatile. The standard sizes available are diameters 10 to 25 mm and lengths 25 to 305 mm.

The helical springs from norelem are machined to the highest precision - the result is, amongst other things, excellent spring characteristics. The basic high quality component is a rectangular coiled wire made of chrome-silicon steel that reacts to pressure. Flat spring ends, ground to a right-angle ensure uniform force transfer and improved seating. The special spring profile enables high alternating and permanent forces and permits use at operating temperatures up to 230 °C. The springs have been heat-treated, abrasive blasted and pre-stressed at block height during production to significantly extend the life expectancy.

The helical springs from norelem are available in four colour coded load grades. The lengths, diameters, force and colours comply with ISO 10243 guaranteeing interchangeability of components within the various load grades.

A tip: When selecting a spring the user should take into account how the spring travel is divided into working travel and preload travel. The smaller the difference between the spring travel and the unloaded length, the higher the expected service life. Select a preload as large as possible and a working travel that is as short as necessary to maximise the service life.