#Product Trends

Choosing Between Nut Splitters and Flange Bolt Cutting Saws

Struggling with corroded nuts and bolts during maintenance work?

During maintenance work, flanged connections often require disassembly, but the nuts on these flanges can become severely corroded from prolonged exposure to the elements. One common tool for tackling seized nuts is the nut splitter, which uses a hydraulic cylinder to split nuts in half. However, nut splitters have some limitations. Each splitter head only fits a specific range of nut sizes, so covering a broad range requires multiple heads, which can be costly. Larger nut splitters are also heavy, often needing multiple operators or lifting equipment for safe handling. Additionally, using hydraulic pressure poses some safety concerns, as built-up pressure can release suddenly when the nut finally splits.

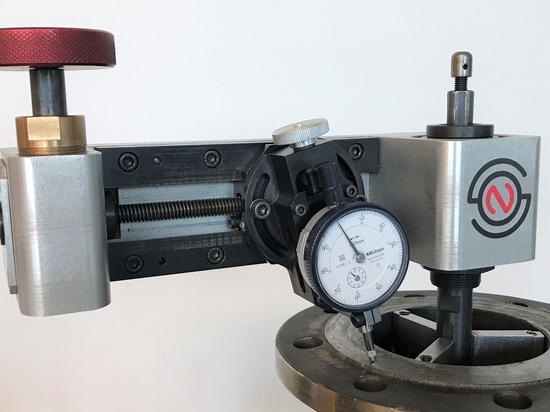

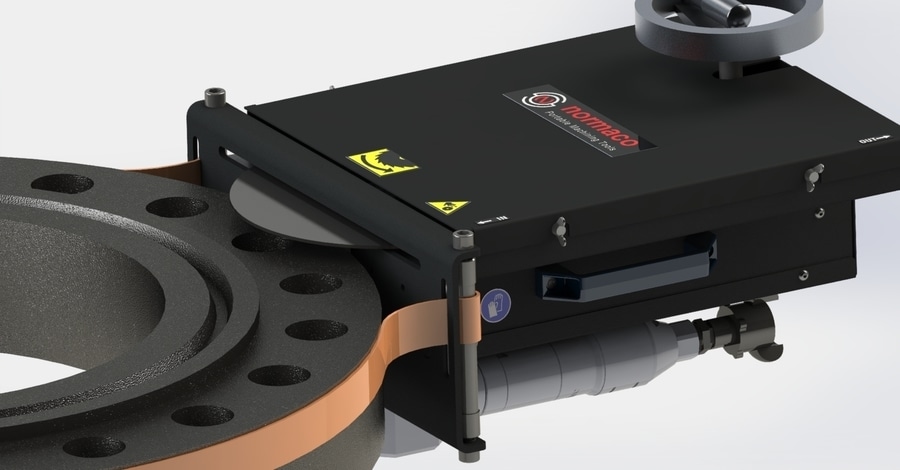

The Flange Bolt Cutting Saw offers an effective alternative for cutting corroded bolts. This tool can handle a wide range of bolt sizes up to M72 with a flexible clamping range, allowing for easy adjustments. Designed with a lightweight, modular construction, the Bolt Saw is simple for a single operator to set up and use. The low-speed cutting operation is spark-free, thanks to its pneumatic motor, which makes it ideal for hazardous environments that require spark-free work methods.