#Product Trends

Air Safety Devices

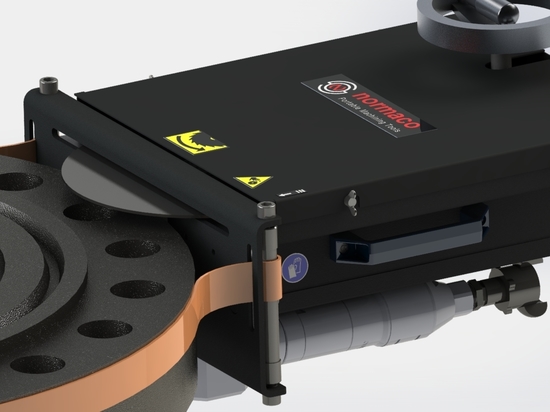

Why Air Safety Devices Are a Must-Have for Air Motor-Powered Tools

What Makes Air Safety Devices Worth It?

The main job of these devices is pretty straightforward: they stop your tools from starting accidentally and let you quickly shut off air supply in an emergency. Sounds simple, but it can make a big difference when things go sideways.

Here are a few situations to think about:

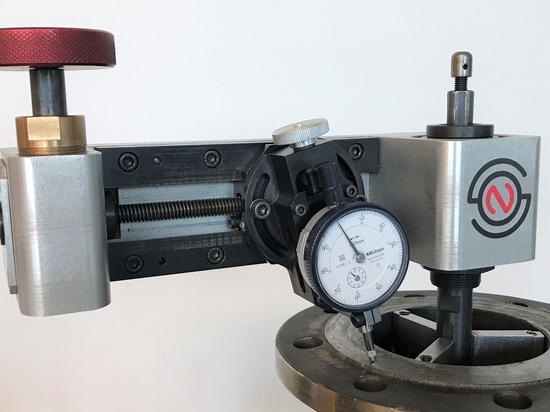

Accidental Starts: Picture this—you’re checking out an air-powered facer, and it suddenly kicks on. Without a safety device, that’s an injury waiting to happen.

Leftover Pressure: Even after shutting down, leftover pressure in the motor can cause unexpected movements when setup or adjusting starts. An air safety device automatically vents this pressure, so you don’t have to worry about it.

Emergencies: On an offshore rig or in a busy workshop, having a quick way to cut off air supply can stop a small issue from becoming a big problem.

The Benefits Speak for Themselves

Fewer Accidents: By blocking accidental starts and venting residual pressure, these devices tackle two of the most common air tool risks.

Fast Emergency Response: An emergency stop lets you kill the air supply instantly—no scrambling.

Longer Tool Life: Built-in filtering and lubrication mean less wear and tear, which is always a plus.

A Small Investment for Big Peace of Mind

At the end of the day, using air safety devices isn’t just about following safety rules—it’s about keeping your team safe and your tools running smoothly. If your work involves air-powered equipment, adding this kind of protection just makes sense.