#Industry News

The value of process instrumentation training

Enhance operational efficiency through targeted training

In the industrial landscape, effective training is more than just a requirement; it is a pivotal component in driving operational success. As industries evolve and technology advances, the need for skilled personnel who can adeptly handle complex equipment and systems becomes paramount.

Enhancing Operational Efficiency:

Operational efficiency is the cornerstone of a successful industrial operation. Well-trained personnel reduce operational errors and optimize efficiency. Training programs focusing on practical, hands-on learning equip employees with the knowledge and skills to handle equipment accurately and effectively.

According to Gallup’s latest employee engagement meta-analysis, business units prioritizing training and engagement are 17% more productive. This correlation between training and productivity underscores the vital role of continuous learning in the industrial sector. Employees who receive targeted training are better prepared to navigate the complexities of their roles, leading to smoother operations and fewer disruptions.

Reducing Downtime and Maintenance Costs:

One of the significant challenges in industrial operations is unplanned downtime, which can be financially crippling. Deloitte reports that unplanned downtime costs industrial manufacturers as much as $50 billion annually. Proper training plays a critical role in mitigating this issue by ensuring that personnel can handle equipment proficiently, identify potential problems early, and perform necessary maintenance tasks.

Trained employees can diagnose and address issues before they escalate, significantly reducing downtime and maintenance costs. This proactive approach saves money and extends the lifespan of equipment, ensuring that operations run without a hitch. By investing in training, companies can create a workforce capable of maintaining high performance and minimizing costly interruptions.

Boosting Employee Morale and Retention:

Employee morale and retention are closely linked to the availability of training and development opportunities. Training programs demonstrate an organization’s commitment to its workforce, fostering a culture of growth and continuous improvement. According to Gallup, 59% of workers consider learning and development opportunities extremely important, highlighting the role of training in job satisfaction.

Panametrics customer Rolando E. shared, “This was the best training class I have attended in over 15 years...,” reflecting the positive impact of training on employee morale. When employees feel valued and equipped with the needed skills, they are more likely to remain loyal to their organization, reducing turnover rates and building a more stable and experienced workforce.

Customizing Training to Meet Specific Needs:

No two industrial operations are the same, and a one-size-fits-all approach to training is rarely effective. Customized training programs tailored to specific equipment and industry requirements are essential for addressing unique challenges. Flexibility in training allows for the inclusion of relevant topics that directly impact daily operations, ensuring that employees gain the most applicable knowledge and skills.

Customized training programs can adapt to an organization’s evolving needs, offering scalable solutions that grow alongside the business. This adaptability ensures that training remains relevant and valuable, providing long-term benefits to employees and the organization.

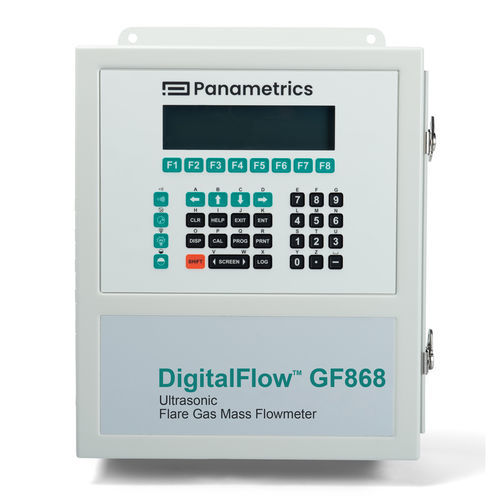

AddING value with Panametrics’ Tailored Training:

The value of process instrumentation training cannot be overstated. The benefits of investing in training are numerous, from enhancing operational efficiency and reducing downtime to boosting employee morale and retention. With our extensive experience and expertise, Panametrics offers advanced training solutions that address the specific needs of various industries.

By focusing on practical, hands-on learning and customizing training programs, Panametrics ensures that organizations using our products are well-equipped to tackle the challenges of today’s industrial landscape. Training is an investment in the future success of your operations. To learn more about Panametrics’ training programs and how they can benefit your team, contact us today to schedule a session tailored to your needs.

Copyright 2024 Baker Hughes Company. This material contains one or more registered trademarks of Baker Hughes Company and its subsidiaries in one or more countries. All third-party products and company names are trademarks of their respective holders.In the industrial landscape, effective training is more than just a requirement; it is a pivotal component in driving operational success. As industries evolve and technology advances, the need for skilled personnel who can adeptly handle complex equipment and systems becomes paramount.