#Trade Shows & Events

Optical quality control solutions on the rise

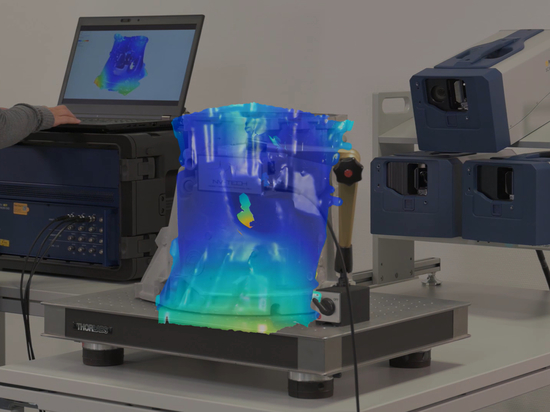

Non-contact and non-destructive measurement and analysis for quality and process control

Quality control (QC) for industrial manufacturing and process control using non-contact, optical measurement and testing solutions by Polytec: from testing acoustic and dynamic properties over surface characterization, length and speed measurement in the manufacturing process of continuous goods to spectral analysis for agriculture, food and chemicals. Polytec quality control solutions open up a realm of applications in quality control. Experience here, how our customers check tolerances, control process stability and secure quality.

Learn about surface metrology giving feedback for manufacturing processes, simplifying user operation with one-click routine measurement recipes at production level. Find out about airborne remote sensing equipped with hyperspectral camera systems as ready-to-fly kits, evaluating objects based on their geometric and spectral signatures from a drone’s view – used for precision farming, forest management, environmental inspections or open mining. Analyze fat, protein and starch content right in the production line, enabling fine adjustments in food, chemical or agricultural manufacturing. Polytec optical testing solutions also cover acoustic, dynamics or noise testing on mechanical component manufacturing, such as typically bearings, actuators, pumps, drives or any other precision mechanics. The acoustic signature reveals defects efficiently in-line, providing a highly reliable pass-fail analysis while reducing false rejects. Learn more here.