#Industry News

Combined speed and thickness measurement in rolling mills

Enhancing the mass flow control

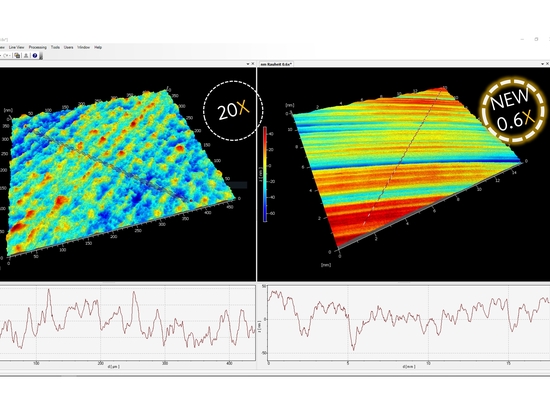

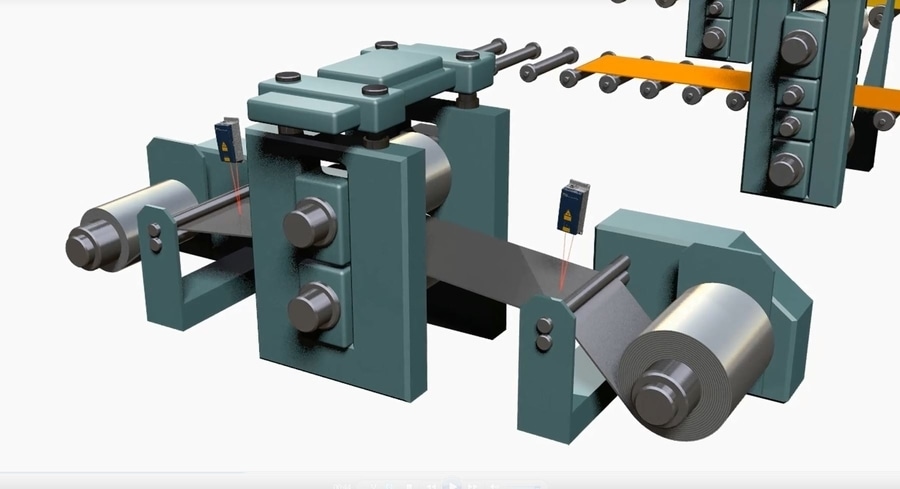

In the metal industry, controlling of the roll gap width is crucial for mass flow control in order to secure a constant material thickness in sheet metal production. Knowing the thickness and speed before and the speed after the roll stand enables fine adjustments of the roll gap for process stability. The strip thickness is usually measured with C-frames in order to measure the speed upstream and downstream of the roll stand, for example with an LSV laser velocimeter. Integrate this robust, industrial laser sensor into the C-frame to save space. The high-precision laser velocimetry avoids slippage and wear, leading to unrivalled reliability in controlling the roll gap, matching thickness specifications and increasing overall process quality.

For sheet metal production, LSV Laser Surface Velocimeters from Polytec are the ideal measurement solution for process control. They measure without contact on almost any material, no matter if shiny, oily or in harsh industrial environments while leaving the measured goods fully intact. Whether measuring the degree of skin pass or stretching, reading the speed or velocity difference - rely on the superior accuracy of this optical encoder, ideally integrated in C-frames.