#Industry News

A Historical Swiss R&D Center to Develop Performance-Critical Miniature Motors

Founded in 1931 in Switzerland !

Founded in 1931 in Switzerland as The Universal Escapement Ltd., Portescap was devoted exclusively to manufacturing products for the clock and watch industry. Our company became quickly famous for the Incabloc shock absorber system which was breakthrough for mechanical watches designs.

Thanks for its passion for precision and customer centric innovation, in 1959, Portescap launched its first ironless rotor DC motor trademarked escapTM. This technology marked the beginning of a series of innovative electric motors which made Portescap, the company we currently know today, as a leading manufacturer of miniature motors for performance-critical applications. In 1981, Portescap made possible a new level of performance thanks to a revolutionary two-phase Disc Magnet motor technology launched in 1981. Continuing with the focus on innovation, Portescap’s first slotless brushless motor was developed and introduced in 1986 using the same coil technology as a DC motor.

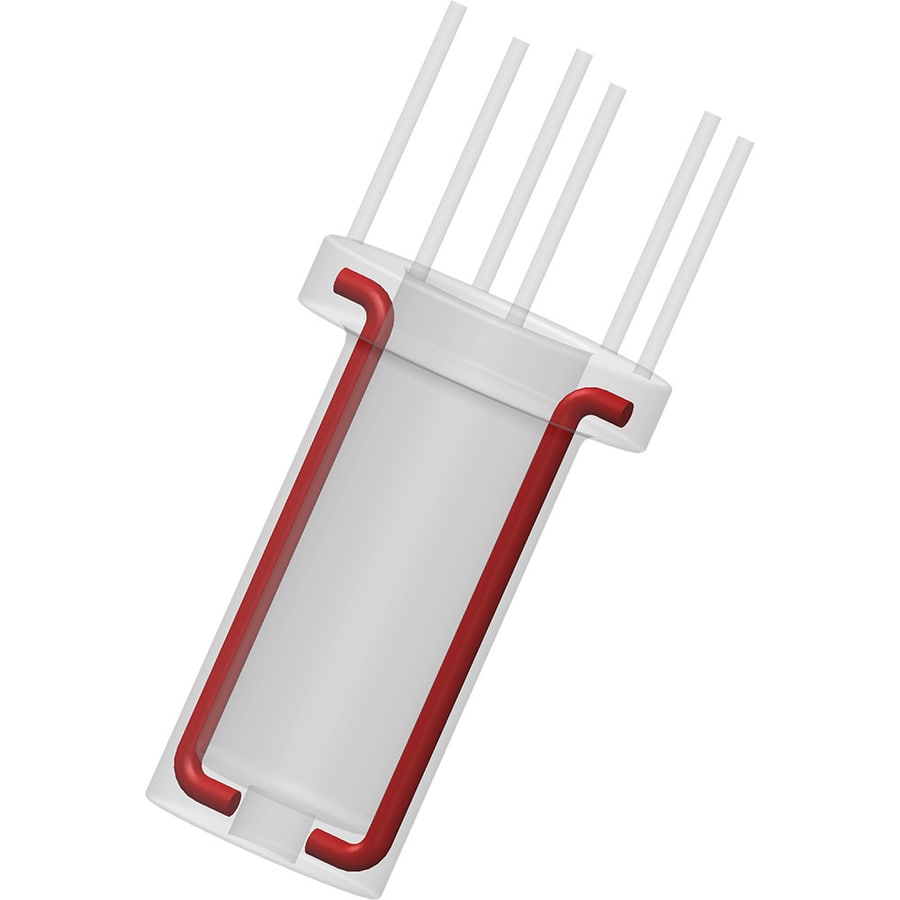

In 2014, Portescap’s R&D team in Switzerland reiterated breakthrough innovation by launching the new Ultra EC™ platform of slotless brushless motors. This unique design is made possible by a new innovative and proprietary coil with a U shape and compacted heads. This specific axial straight shape of the wire allows to use the full potential of the copper and magnet while highly reducing the Joules losses. With this better efficiency, the motor can have a cooler operation perfect for demanding medical devices or various industrial applications.

The Ultra EC platform offers three product lines to fit into most applications: Ultra high torque (ECT), Ultra high speed (ECS) or Ultra-performance at an optimized cost (ECP). For customers looking to integrate our Ultra EC motors into their application, we have a team of Applications Engineers based in our Swiss office to guide you in your selection. Our dedicated team of Applications Engineers will understand your needs and thanks to their experience in demanding applications, they will help you to find the best motion solution for your application. Thanks to their knowledge of all Portescap technologies (Brushless, Brush DC, Steppers, Gearboxes, Encoders…), they are able to propose high performance innovative solutions which can allow for breakthrough product results. Most importantly, we ensure support from beginning to end. To ensure you are fully satisfied with the solution and all customizations, our team will follow up on your project internally with the different departments until the running production.

To maximize breakthrough design impact for our customers, Portescap is focused on early collaboration and custom engineering. So, the earlier you engage with us, the more opportunity for breakthrough results. For brushless motors, depending on the size of the project and the technical challenges, our Swiss R&D team can leverage their long experience and capabilities to develop highly customized products to propose the best solution and along with our Applications Engineering team, will collaborate with you to achieve the most optimal result.

What are some of the common customization possibilities of our Brushless Slotless Motors?

Mechanical interface: shaft, flanges, holes

Electrical interface: special brushless coils to adapt to preferred voltage and speed

Performance optimization: new magnetic design, new motor size, new technology

Adaptation for special environment: waterproof design, ball bearings, sealing…

Special customer requests (pinions, cables, connectors, brakes, fan…)

Encoders design & assembly Gearboxes design & assembly

The team at our Portescap Switzerland office includes specialized engineers who have all the tools to design, test and assemble complete motors, gearboxes, and encoders. Electro-magnetic, mechanical, and thermal simulations can be done to design optimized solutions for your specific needs. Losses, temperature, and lifetime can also be calculated for a specific cycle in order to select and validate the optimal solution.

We also have a mechanic team to support prototypes. They can manufacture challenging components and tooling with high precision. Standard components are stocked, and we also work with some carefully selected suppliers who provide some components. These complex prototypes can be assembled in the lab using the same equipment as in production. Overall, this allows Portescap to provide customized solutions in short lead-time while ensuring great quality.

Looking for some support determining the best solution for your new product development? An Application Engineer can help you. Speak with us today!