#Industry News

RAS unveiled the New MiniBendCenter 2 at EuroBLECH

Innovative Bending Technology with New Software and Robotics for Maximum Flexibility and Efficiency

At this year’s EuroBLECH in Hanover, RAS Reinhardt Maschinenbau GmbH presented the MiniBendCenter 2, a fully automated solution for precise single and series production of bent parts. Equipped with cutting-edge technology, the MiniBendCenter 2 sets new standards in flexibility, speed, and precision.

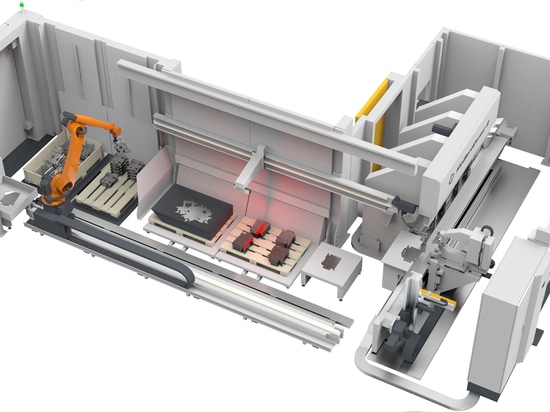

The MiniBendCenter 2 is the world’s most unique folding center specifically designed for small parts. It combines advanced robotics with an innovative software solution to achieve the highest levels of flexibility and efficiency. The new MiniBend-Office software and the integrated robot for fully automated loading and unloading make the system ideal for 24/7 operation.

New Standards with MiniBend-Office Software

The MiniBendCenter 2 comes with the new MiniBend-Office software, a standalone solution that replaces previously used CAM software and SolidWorks. Through a partnership with Euclid, the flexibility of the software is significantly enhanced, allowing for fully integrated control. Thanks to the MiniBend-Office software, only one software solution is now required, which handles both programming and simulation, uniting the entire process on a single platform. This reduces complexity, increases efficiency, and simplifies operation.

Intelligent Robotics for Loading and Unloading

The intelligent robotic system of the MiniBendCenter 2 handles both loading and unloading of workpieces. With highly precise servo-electric controls, the system sets new benchmarks for efficiency and precision. The vacuum suction unit features four individually controllable suction cups, enabling efficient handling of parts from stacks or bulk material. The finished bent parts are stacked in a space-saving and stable manner. The pallet change can take place safely and seamlessly during operation. Thanks to the robot’s seamless integration into the software, additional teaching is not required.

Automated Processes for Continuous Operation

The MiniBendCenter 2 enables the processing of sheets up to 600 x 600 mm and a material thickness of up to 3 mm in steel. Due to the automatic bending technology in both directions, no turning of parts is required, avoiding unnecessary movements and significantly reducing processing time. Combined with the automatic tool setup, the machine can run continuous 24/7 production in so-called "ghost shifts" with both series and individual parts.

“The MiniBendCenter 2 sets new standards in sheet metal processing. It combines speed, efficiency, and precision in a compact design,” explains Thomas Berger, Project Manager Automation at RAS. This makes the system ideal for a wide range of applications.