#Product Trends

Guidance to configuring enclosures – from Rittal Electrical safety is already assured

Security is a high priority with electrical switchgear. To prevent injury to persons or damage to property, a number of standards and regulations have to be followed. These also cover the potential equalisation between all the metallic parts of an enclosure. The TS 8 baying system from Rittal shows how safety can be achieved in many applications through automatic potential equalisation without having to separately earth all the panels.

The earthing of metallic parts on electrical systems for safety reasons is prescribed virtually everywhere. This applies to all electrical equipment and units – from simple lamps to low voltage distribution systems. The reason is quite clear: If an error occurs (if, for example, an enclosure part could become live) it would cause harm to persons. And an enclosure needs to provide protection from contact with precisely such hazardous voltage. In low voltage switchgear, earthing must be provided to which all the metal frame and enclosure parts endangered by stray voltage have to be connected.

Attaching the earthing straps

In order to perform a potential equalisation of this nature, in which all metallic parts are connected to earth, earthing straps of copper wire are usually provided. These are flexible and can therefore safely contact moving parts (such as doors) to the enclosure. In an enclosure, the earthing straps usually also have to be connected with the frames, the side panels, the enclosure roof or other panels. Once all the earthing straps have been correctly fitted, there is an equalisation of potential, and all the enclosure components can be earthed via the protective conductor of the voltage supply. Since the workshop personnel have to attach the earthing straps manually during assembly, this is also a source of error. Should a strap be forgotten, the finished switchgear will be able to function, even though it might endanger people in the event of a fault.

Potential equalisation even without an earthing strip

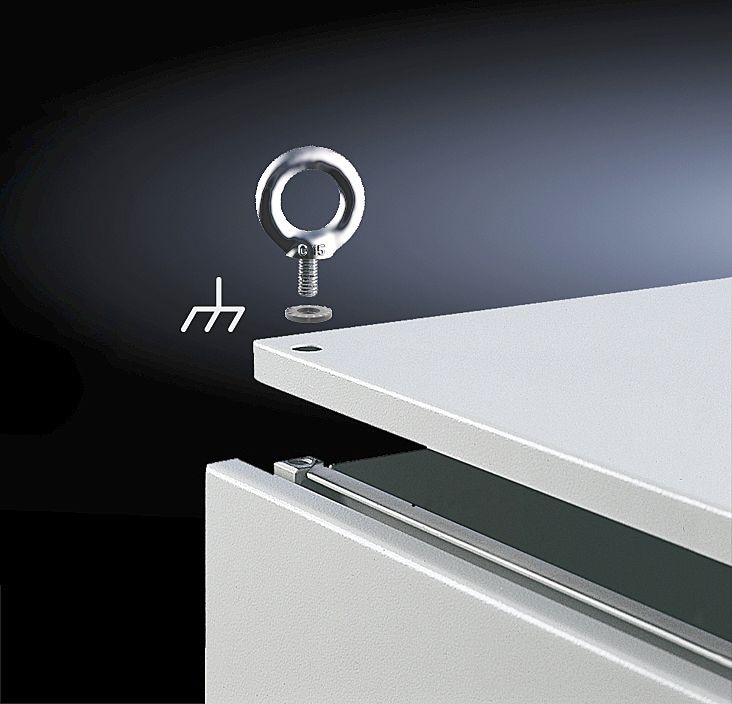

To make it easier to implement electrical protection, Rittal has developed an effective solution with the TS 8 bayed enclosure system: During assembly, the side panels, enclosure roof, rear panel and gland plates are automatically connected to the frame conductively. This way, potential equalisation is achieved, without which these parts would need to be contacted with earthing straps. This solution is implemented using special claws or washers; these press through the electrically non-conductive surface coating of the panels during assembly, so achieving a reliable contact. This means that all the flat panels are electrically connected to the frame, so that earthing straps are no longer needed in many applications. An earthing strap only needs to be attached to the enclosure door. The contact resistance between the panels and the enclosure frame is less than 0.1 Ω, the value demanded by the DIN EN 62208 empty enclosures standard.

Simplified installation and greater safety

In the workshop, this automatic potential equalisation leads to a reduction in the amount of material needed and to easier assembly: The time-consuming attachment of up to seven earthing straps per enclosure is no longer necessary. In addition to these savings in terms of material and time during assembly, it is also easier to disassemble and re-assemble the panels, because the earthing straps do not have to be removed and re-attached each time. In the course of risk assessment, users must decide whether the design measure of automatic potential compensation is sufficient or whether separate earthing straps are needed to meet the technical safety requirements.

Benefits at a glance

Automatic potential equalisation with the Rittal TS 8 baying system offers the following benefits:

• It saves mounting as many as seven earthing straps

• It simplifies the assembly and disassembly of all the panels