#Product Trends

SND40 - Weld Seam Detection for Stabilizer Bars

Stabilizer bar production is still subject to the current requirements of reduced weight and high torsional rigidity in vehicle construction, which results in thinner tube walls but higher strength levels. Flexible and productive machine concepts are required as an answer to shorter development cycles and smaller batch sizes.

WPT WAFIOS Production Technology, in collaboration with Schneider Maschinenbau, as well as partners representing notable names in the German technology industry, have designed a fully automatic, highly flexible, and modular manufacturing system for bending and rod end flattening of stabilizer bars.

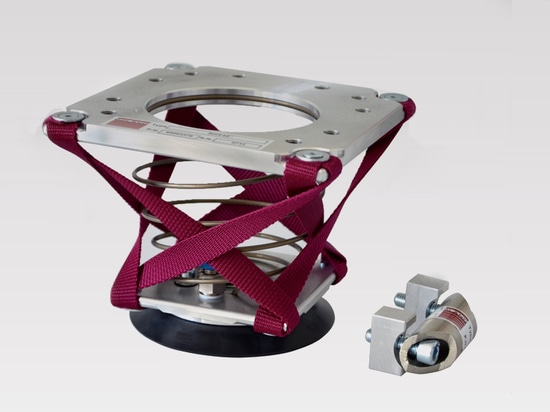

The SND40 Weld Seam Detection System of ROLAND ELECTRONIC has been implemented successfully within this manufacturing system.

The connecting, interlinking and automation of different modules demonstrate the boosting productivity. At the same time this application is a good example of the networked manufacturing era – Industry 4.0, as it is known.

SND40 offers a maximum of flexibility and process reliability of Weld Seam Detection of pre-annealed tubes and rods which are becoming highly popular within the automotive industry, and there are no signs of this trend slowing in the future; it is set to accelerate.

Thanks to the use of the SND40, the Weld Seam is detected successfully and positioned to an angle which experiences the least material stresses due to subsequent bending and forming, respectively to a non-critical angle. Thus, with the SND40, repeatable tube bending and highest stabilizer stability not subject to excessive material fatigue is achieved. Even non-visible Weld Seams of pre-annealed tubes can be detected and positioned with the SND40, as shown in the video (https://www.youtube.com/watch?v=RDuTw2Ar6rg).