#Product Trends

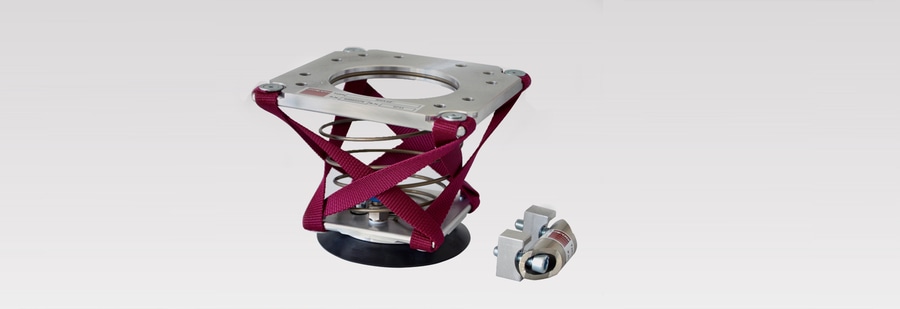

SHX – a sensor bracket with unique features

The SHX sensor bracket has been designed for the effective integration of Double Sheet Sensors into Vacuum-Toolings.

It is also ideally suited for retrofitting. Due to a combination of a strap set with a central spring, this bracket does not require any guides. This innovative solution pushes the bracket to ideal performances. The placement on slanted TWB-Stack has become easy to control, in particular through the now even larger opening

in the upper plate. This has been increased from 90 to 105 mm - thus setting up has now become even more comfortable. Collisions of the sensor, respectively the sensor plug to the upper plate have become impossible even at most oblique stacks.

An essential property of a good sensor bracket consists in the flexibility of its suction cup. During compressed condition this is a prerequisite for performing a reliable Double Sheet Detection. This flexibility is however contrary to the desire to be as rigid as possible in its decompressed condition. Due to the combination of the strap set and spring, this balancing act has been solved ingeniously with the SHX sensor bracket.

A practical side effect is that there are no guides required. Wear, canting and stiffness belong therefore to past.

Another positive effect is the significant weight saving, since this spring strap system has only a low mass.

Such a performance places the lightweight SHX sensor bracket worldwide to No. 1 on available solutions.

The SHX spring mounted sensor bracket has been designed in decompressed condition for high lateral acceleration up to 2g.

Thus it is no longer the limiting component of transfers.

The SHX sensor bracket solves definitively the known problems of such applications. So far, the lack of flexibility prevented adaptation of the suction plate for smooth and planar surfaces; in consequence, the measuring behaviour of the sensor was compromised. Additionally the risk was high for vacuum not to be generated promptly or with a delay. At modern cycle times this is not acceptable.

An important point is also the easy maintenance; since this sensor bracket has no guides, it eliminates a permanent set-up. A lot of time, trouble and material will be saved.

More and more users enthusiastically switch or upgrade to this sensor bracket. There are fewer failures, less maintenance is required, and thus more uptime is guaranteed.