#Industry News

Extraordinary maintenance of industrial shredder: a real case

When routine maintenance is no longer sufficient, extraordinary is an opportunity

The daily work of an industrial shredder is often very demanding, especially in cases where it has to grind especially wearing materials such as tyres, plastic films and agricultural tarpaulins, electric cables and metals.

Thus, harsh working conditions, even within multiple shifts, can lead to wear on the blades, blade shafts, bearings and seals and selection screens, for which routine maintenance is no longer sufficient to ensure optimal operating performance in terms of efficiency and effectiveness, and performance can drop significantly.

In this case, it may become necessary to perform extraordinary maintenance work on the industrial shredder to restore it to its original factory conditions.

The intervention planned with the customer normally involves pick-up of the machine for disassembly on the ground at SatrindTech's service department.

Methods of intervention

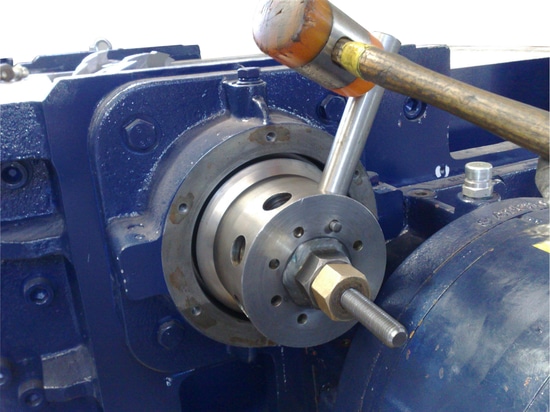

As it proceeds, complete disassembly allows our technicians to analyse all the parts in order to evaluate which are the most worn and to propose a suitable solution to the customer for extraordinary maintenance of the industrial shredder.

In most cases, this involves:

• Blade re-sharpening

• Condition of the hexagonal blade shafts (blade marking)

• Replacement of all seals (O-rings, oil seals) and mechanical seals

• Replacement of the seals (packings) of the intermediate bulkheads protecting the bearings

• Restoration of worn seats in which the seals are working by means of bushing

Intervention also involves verification of the conditions of the motor both as regards electric motors and hydraulic pumps and motors, for which in some cases an overhaul by the manufacturer may be necessary.

At the end of the extraordinary maintenance of the industrial shredder, re-testing follows according to SatrindTech's control specifications and only after the product has been issued to the customer.

A real case

The video below instead shows extraordinary maintenance of the industrial shredder with 3 shafts in the 3K 60 HP series, equipped with 4 blades, 30 mm-picks and selection screens with 50 mm holes.

We have completely disassembled and overhauled the shredder, resharpened all the blades and replaced seals and mechanical seals.

The blade shafts were in good condition and so were the gear wheels of the main reduction unit. The material selection screens were also in no particular conditions of wear.

All operations are performed within SatrindTech's technical service department, including grinding the blades to the most suitable thickness and tolerance values.

Our Service is at your disposal to evaluate all your needs for routine and extraordinary maintenance of your industrial shredder.