#Industry News

The shredding of pharmaceutical chemicals

Energy recovery objective

There are companies closer to us than we might think who make waste disposal aimed at energy recovery their vocation, their target. They are able to design and build plants for all types of waste treatment, especially in the chemical and oil sectors.

This is the case of a company in the province of Bergamo, to which we have just delivered a 4-shaft shredder of the 40 HP 4S series. The series is equipped with a special loading hopper, to be inserted in a new production line for the shredding of pharmaceutical chemical products, mostly blisters, plastic, drums up to 75 L bags and other similar material.

The customer, with the choice of the 4S shredder, will be able to achieve a homogeneous size grind functional to the production cycle, as the shredder is equipped with 40 mm blades (2 and 5-pick) and a selection grid with 50 mm diameter holes.

Series 4S focus

The 4S series, declined in the 40 and 60 HP versions, stands out for some features that make it more effective and efficient than the two and three-shaft shredders:

• The blade shafts also shred in reverse, thus increasing productivity; moreover, working in pairs, they are able to manage separate or joint reversals according to the process requirements.

• The PLC program with which the shredder is managed stores different customised shredding phases in order to adapt the shredding process to the material.

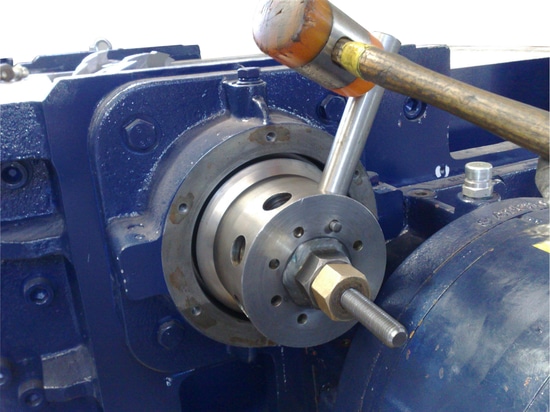

• The 4S series also reduces maintenance time and costs, as its innovative technical features allow for blade replacement, both due to wear and configuration changes, more quickly than other series on the market: the blade shafts can be easily removed from the body, inserting the new set and reducing downtime.

The loading hopper has been studied and built based on the explicit needs of the customer, so that it can be inserted in the production line, just like a well-tailored suit.

All this certainly makes the shredding of pharmaceutical chemicals more efficient and fully meets the customer's needs, thanks to the flexibility offered by the product.