#Product Trends

EasyCUBE Pall in the E-commerce sector

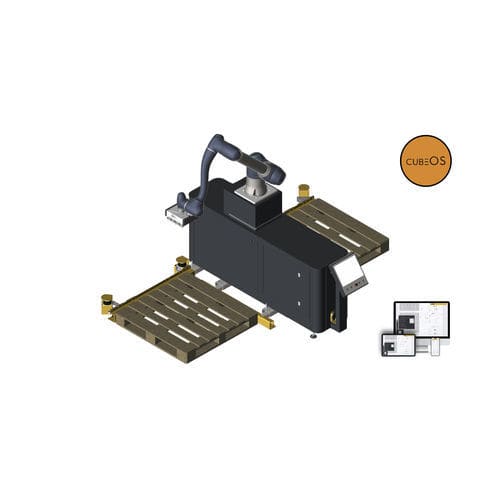

In this application, four EasyCUBE Pall stations were used for the palletization of four customer lines dedicated to inserting various products into boxes.

In this application, four EasyCUBE Pall stations were used for the palletization of four customer lines dedicated to inserting various products into boxes.

Resolved Issues:

- Improvement of Working Conditions: Automation reduces operators’ exposure to repetitive tasks and ergonomic risks, helping to minimize potential health issues related to handling heavy loads and improper postures.

- Process Uniformity and Quality: The use of robots ensures consistent, precise, and uniform palletization, reducing errors or issues related to the incorrect arrangement of boxes on pallets, thus improving safety and load integrity during transport.

- System Flexibility: The automated palletizers can handle a wide range of products and box sizes, quickly adapting to production changes without requiring lengthy modifications or manual reconfigurations.

- Increased Productivity: The palletizers can operate continuously and without interruptions, enhancing the overall efficiency of the production lines and reducing downtime associated with manual handling of the palletization process.

- Monitoring and Traceability: The automated palletization system allows for continuous monitoring of the boxes and formed pallets, providing real-time data and improving traceability of operations and logistics optimization.