#Industry News

EasyCUBE in the Automotive sector

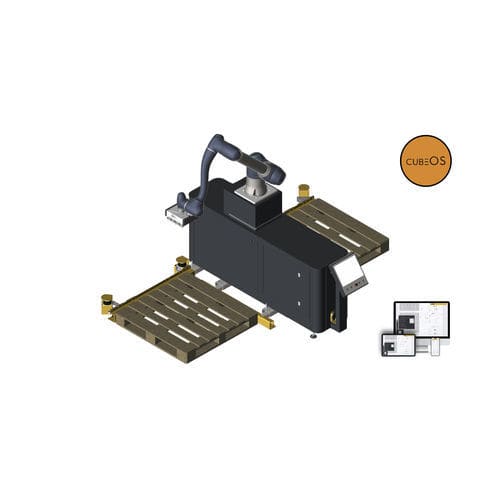

In this application, two EasyCUBE stations with collaborative robots were used, equipped with a lance capable of delivering a high-pressure air jet for targeted drying of the wetter areas of tractor frames.

In this application, two EasyCUBE stations with collaborative robots were used, equipped with a lance capable of delivering a high-pressure air jet for targeted drying of the wetter areas of tractor frames.

Resolved Issues:

- Uniformity and Quality: The cobots ensure precise and uniform drying across all surfaces of the frame, reducing human errors and improving process quality while minimizing the chances of defects or inadequately treated areas.

- Flexibility: The presence of two collaborative robots allows for the drying of different types of frames, easily adapting to various tractor models without requiring structural modifications or prolonged setup times.

- Workplace Safety: The use of collaborative robots eliminates the need for operators to manually perform tasks that could be hazardous or physically demanding, improving safety conditions in the factory.

- Labor Hours Savings: The drying task, which previously required dedicated personnel, is now managed by the robots, allowing operators to be engaged in higher value-added activities.

- Space Reduction: Automation with collaborative robots optimizes production space due to a more compact configuration compared to traditional manual workstations.

- Monitoring and Traceability: The automation system allows for real-time monitoring of the drying status of each frame, ensuring quality control of the process and traceability of the operations performed.