#Product Trends

AUTOMATION

Do you have the right partner?

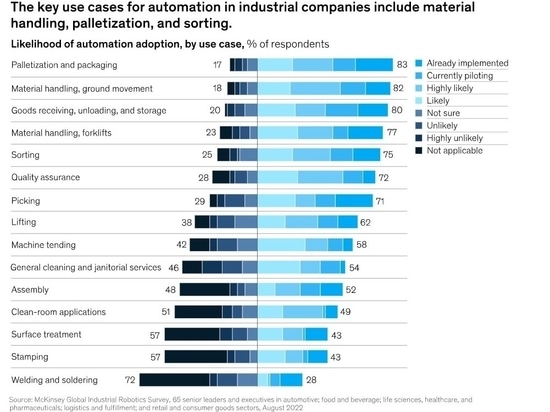

The integration of induction brazing systems into production lines is a trend that has increased by around 20% in the last five years to the detriment of flame brazing processes. Among the reasons for this change is undoubtedly the greater integrability of induction brazing systems, thus having the possibility of automating the process. Automation, as reported by the McKinsey & Company study, will account for 25% of company investments in the next five years.

The steps that make up a brazing process may seem simple, but in reality they present many critical points that need to be attentive when deciding to switch to automation process. Again according to the study by McKinsey & Company, welding and solding are the processes that still have a lot of room for improvement and study in terms of automation. In fact, as seen from the graph displayed, this is the sector that meets with a series of difficulties and holdback and a lower propensity for automation.

For this reason it is essential to work with a partner able to tackle these problems. The experience accumulated by Seit Elettronica in automating welding processes allows us today to guide our customer along the path that resolves critical issues and optimizes processing.

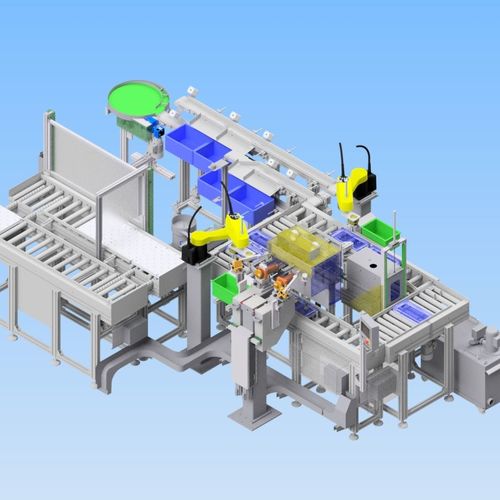

Therefore, thanks to the working method on how Seit approaches new projects and applications, we have come to create platforms that are based on three distinct phases as follows:

1. Loading and handling of the workpiece for preparation for brazing

2. Brazing controlled and monitored by temperature control devices

3. Controlled cooling and workpiece unloading

FIND OUT HOW TO AUTOMATE YOUR BRAZING PROCESS WITH US