#Industry News

Screw air compressor installation program debugging

Air compressor selection Modeling is the first step in purchasing an air compressor. Each manufacturer has different requirements for the air supply volume and compressed air quality of the air compressor. The manufacturer selects the air compressor

1. The installation of the air compressor should comply with the relevant local laws and regulations, and strictly abide by the following regulations:

(1) The air compressor should be hoisted by lifting equipment with a load-bearing capacity greater than the weight of the unit, and the hoisting speed should be within the permitted range;

(2) Try to install the air compressor in a cool, clean and well-ventilated place to ensure that the air inhaled by the air compressor is clean and has the least moisture content;

(3) The air inhaled by the air compressor is not allowed to contain flammable and corrosive gases, so as not to cause explosion and internal corrosion;

(4) The air-cooled machine should have an exhaust fan or an air duct to guide the hot air out to the outside, so as to avoid the circulation of the hot air to the air inlet;

(5) The discharge of sewage and waste oil from air compressors shall comply with the regulations of the local environmental protection department;

(6) Guide the power supply line of the air compressor to match its power and install safety devices such as air switches and fuses. In order to ensure the reliability and safety of electrical equipment, it must be grounded. In addition, it is necessary to prepare the pipeline laying before starting the machine, check the valve opening status of the pipeline system, and close the vent valve. Some air compressors with post-processing devices sometimes require post-processing manufacturers to operate on site. After the inspection is correct, the equipment can be operated.

2. In the process of debugging and running, you should pay attention to the following points

(1) Debugging of new machines shall be carried out by commissioning personnel designated or approved by the company;

(2) Before starting up, make sure that there is no one in the unit, check whether there are forgotten items and tools, and close the door of the unit; when starting up, notify the people around the unit to pay attention to safety;

(3) During trial operation, strictly check the running direction of the air compressor. If it is reversed, stop it immediately, otherwise the air compressor will be damaged (pay attention to each factory power inspection!)

(4) The air compressor cannot work under the exhaust pressure specified on the nameplate, otherwise the motor will be overloaded and burn out;

(5) When the air compressor is under remote control, the machine may start at any time, and it should be listed as a reminder;

(6) When the screw air compressor fails or there are unsafe factors, do not start it forcibly. At this time, the power supply should be cut off and marked clearly.

Management and Training

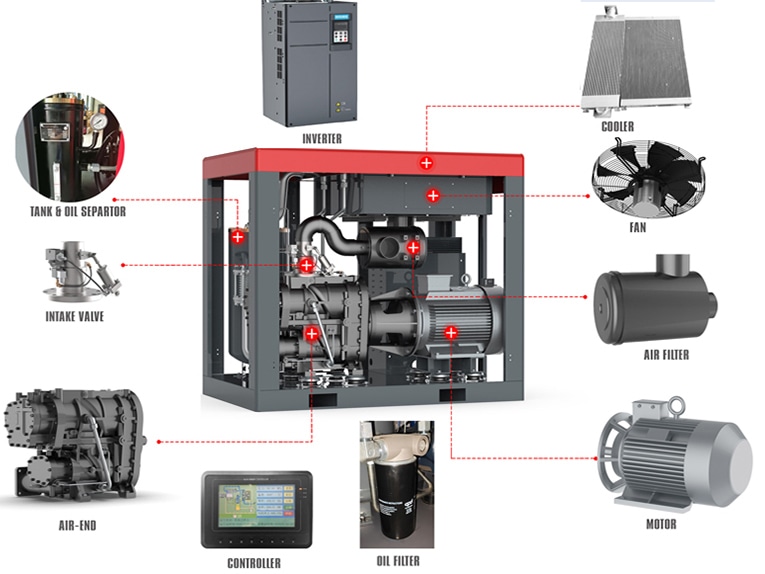

The training of operators includes the training of technical personnel and management personnel, and this work belongs to the training of sales personnel and management personnel. The main content of the lecture includes the structural principle of the air compressor, equipment maintenance, overhaul, and troubleshooting. If the conditions are good, the courseware projection equipment can be used to explain, and the explanation will be combined with the actual equipment.