#Product Trends

An industrial guide to the best electronic adhesive manufacturer

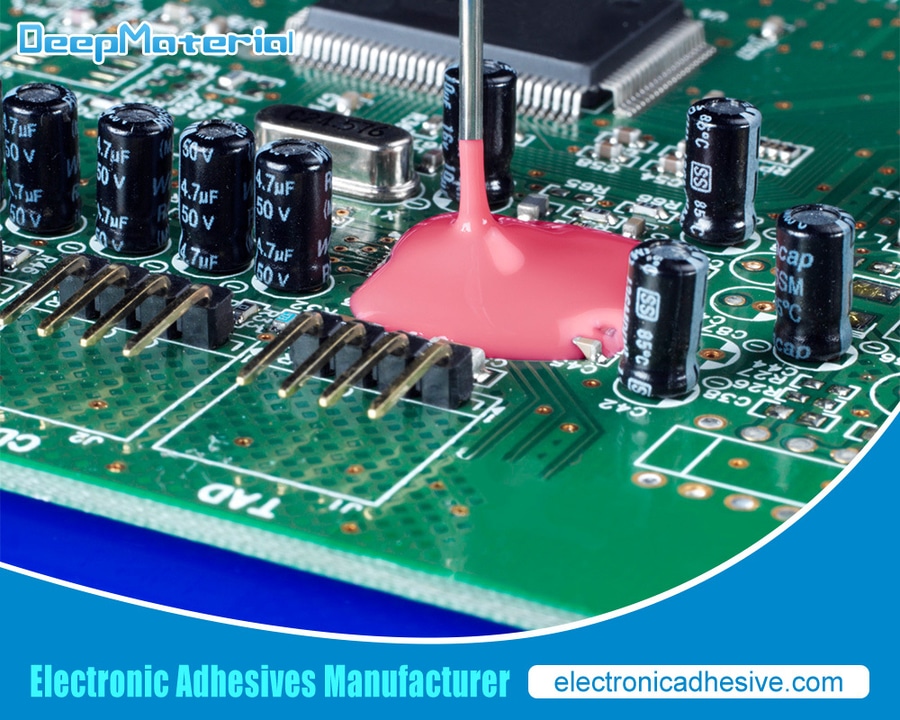

Best Electronic Adhesive Glue Manufacturer

An industrial guide to the best electronic adhesive manufacturer

Electronic adhesives are important chemical non-metallic substances that are used to glue, bond, or hold materials together. Adhesives are very important for product assembly in the electronics industry. Due to the level of sophistication of many consumer electronic goods, they usually require several adhesives to be completed.

Electronic adhesives offer manufacturing facilities a wide range of benefits in comparison to mechanical fastening methods like welding or soldering. Electronic adhesives offer manufacturers such benefits like:

Can be easily applied to different materials.

Evenly distributes material loads.

More preferred over traditional mechanical fastening systems.

A typical electronic adhesive manufacturer should produce the following adhesives such as:

White glue

Hot glue

Epoxy adhesives

Cyanoacrylates

Anaerobic glue

Best Electronic Adhesive Manufacturer in China

Manufacturers of electronic adhesives

Electronic product makers usually depend on an electronic adhesive manufacturer to produce the right type of bonding agent for their production facility. Without electronic adhesive manufacturers, the entire electronic industry will find it difficult to assemble their products. Therefore, to cater to an evolving market, adhesive manufacturers usually produce a wide range of industrial glues that are used for various applications in the electronics industry. This guide to electronic adhesive manufacturers elaborates on their importance to the general electronics industry.

A large collection of adhesive products

An adhesive manufacturer can have as many as 3,000 grades of engineered adhesives that are used for various industrial applications and purposes. Adhesives for industrial use come as UV-curable materials, silicone systems, epoxy solutions, and more. Many electronic adhesive manufacturers specialise in the production of a wide range of adhesives that are used for different applications such as:

Gaskets

Encapsulation

Potting

Sealing

Bonding

Large quantities of adhesives available

Electronic adhesive manufacturers have the needed capacity to meet the various demands of their customers. This means that they can produce large batches of specific adhesives based on gallons. Customers with electronic assembly facilities can request sizes that range from 50 to thousands of gallons. The quantity of adhesive needed depends on the specific application and size of the customer’s facility. With such a huge quantity, adhesive manufacturers cater to both industrial and commercial markets.

Excellent quality assurance policies

An electronic adhesive manufacturer usually should have a great quality assurance/control policy. This is what helps them maintain their competitive edge in the Industry. An electronic adhesive manufacturer should be able to ensure that each step of the adhesive production process is executed according to best practices in the industry. A robust quality assurance policy ensures that their adhesives work as expected when used by customers. Many electronic adhesive manufacturers have highly appreciated quality certifications that demonstrate that they follow accepted standards and procedures when sourcing, manufacturing, and packaging all their adhesive products. They also have documented processes that shield product customers from liabilities if there is a problem. Customers need to choose quality-certified adhesive manufacturers that have robust processes for material sourcing, production, inspection, testing, distribution, and shipping.

In-house adhesive engineering experts

Many electronic adhesive manufacturers have in-house adhesive engineering teams that help them come up with various innovative adhesive products to meet growing market demands. Adhesive manufacturers that have in-house engineering design teams usually have more market traction than those that lack this strategic department. These teams are very valuable for the production of all types of electronic adhesives that meet varying market conditions and industrial applications. Apart from creating sophisticated and authentic adhesive products, this department can also make useful changes to help the facility run smoothly.

Automated adhesive products facilities

The best electronic adhesive manufacturers are known to have automated production facilities. For these manufacturers to meet the demands of modern-day electronic makers, they have automated facilities that cater to the production of various adhesive products such as sealants, glues, epoxies, resins, chemicals, potting materials, and so on. Manufacturers usually have fully automated production facilities that need little or no effort to control. This is how they ensure that their quality control policies are always implemented with each batch of adhesive product that they produce. With an automated production facility, they ensure that each product is produced according to the finest detail. The use of smart computer systems integrated with sophisticated machinery means that the entire process of adhesive manufacture is monitored and controlled to maintain high standards.

Timely product delivery

In as much as electronic adhesive manufacturers have hundreds of glues and industrial sealants, they also manufacture special adhesives based on specific technical data sheets as submitted by the customers. Regardless of how difficult or challenging a certain adhesive production process may seem, they ways work to meet strict deadlines. Many electronic adhesive makers have enhanced production facilities and processes that help them meet all types of customer demands. This is very important in the electronics industry where all types of adhesives for lenses, camera modules, fibre optics, glass, LCDs, screens, touchscreens, and so on are needed. Regardless of the finesse and attention to detail needed to produce a specific adhesive, manufacturers always strive to meet the deadline of all customers. This is how you know that you are dealing with a world-class adhesive maker.

Minimum product order quantity

An electronic adhesive manufacturer usually has entry-level minimum product order quantities to ensure that small and medium-sized enterprises can afford their products. This means that they should be able to cater to all types and sizes of businesses. Customers can order from the minimum accepted other quantity to thousands of products. The manufacturer while being able to meet large capacities of adhesives product manufacture should also be able to cater to the needs of small-scale customers.

Electronic Adhesive Glue Manufacturers And Suppliers

Good product pricing

Apart from quality electronic adhesives, customers want favourable product pricing. An electronic adhesive manufacturer should be affordable. This is a core element of a reliable manufacturer. They should be able to have quality products that customers can afford. This is very important when a customer needs large quantities of a specific adhesive product. Apart from product quality and timely delivery, the cost is another important element that helps electronic manufacturers decide whether or not to use a specific electronic adhesive manufacturer.

For more about choosing the best electronic adhesive manufacturer, you can pay a visit to DeepMaterial at https://www.electronicadhesive.com/about/ for more info.